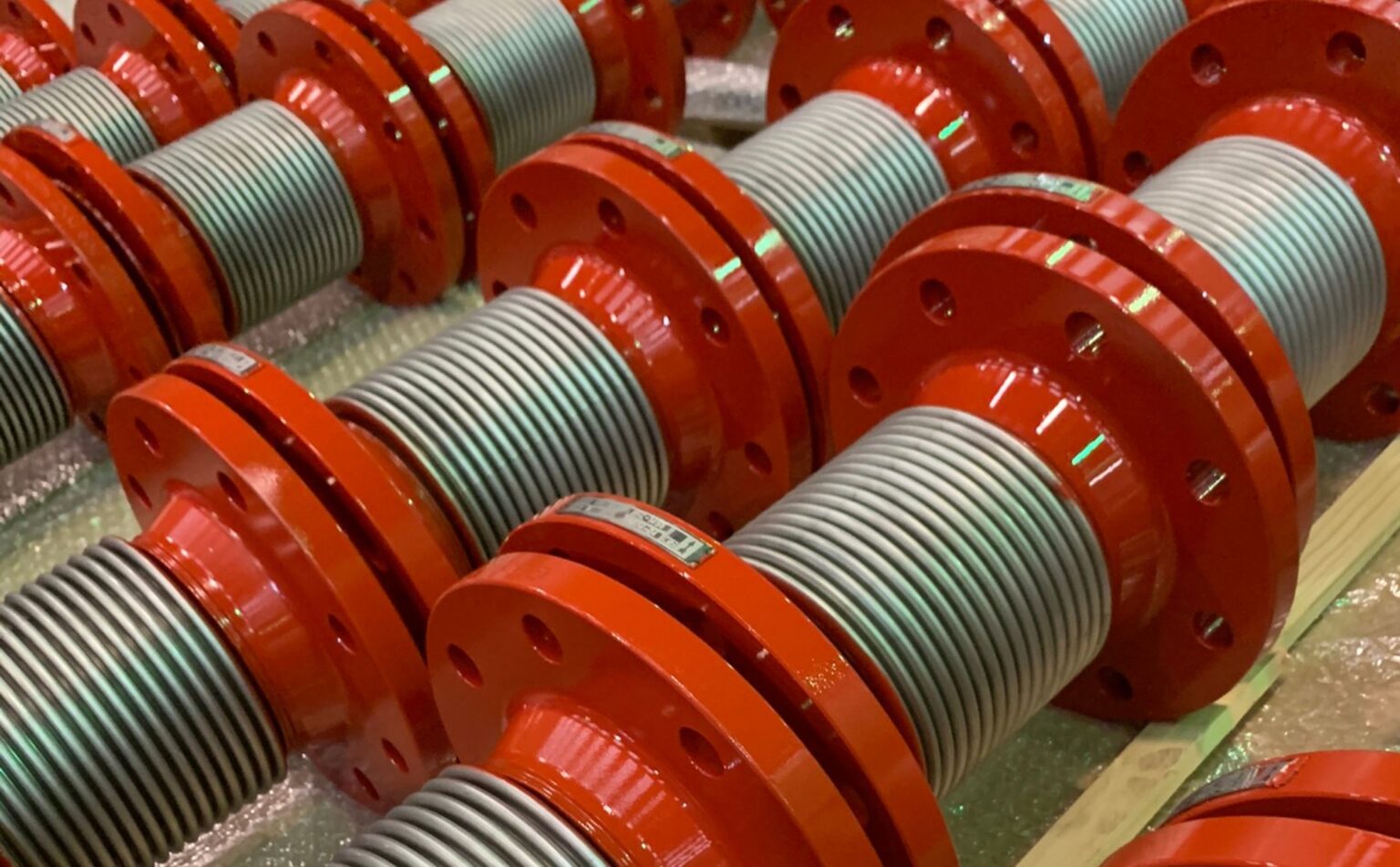

Metallic Joints

Custom design for extreme conditions

Catalogued according to Coraci S.A. standard

Find the joint that best suits your needs

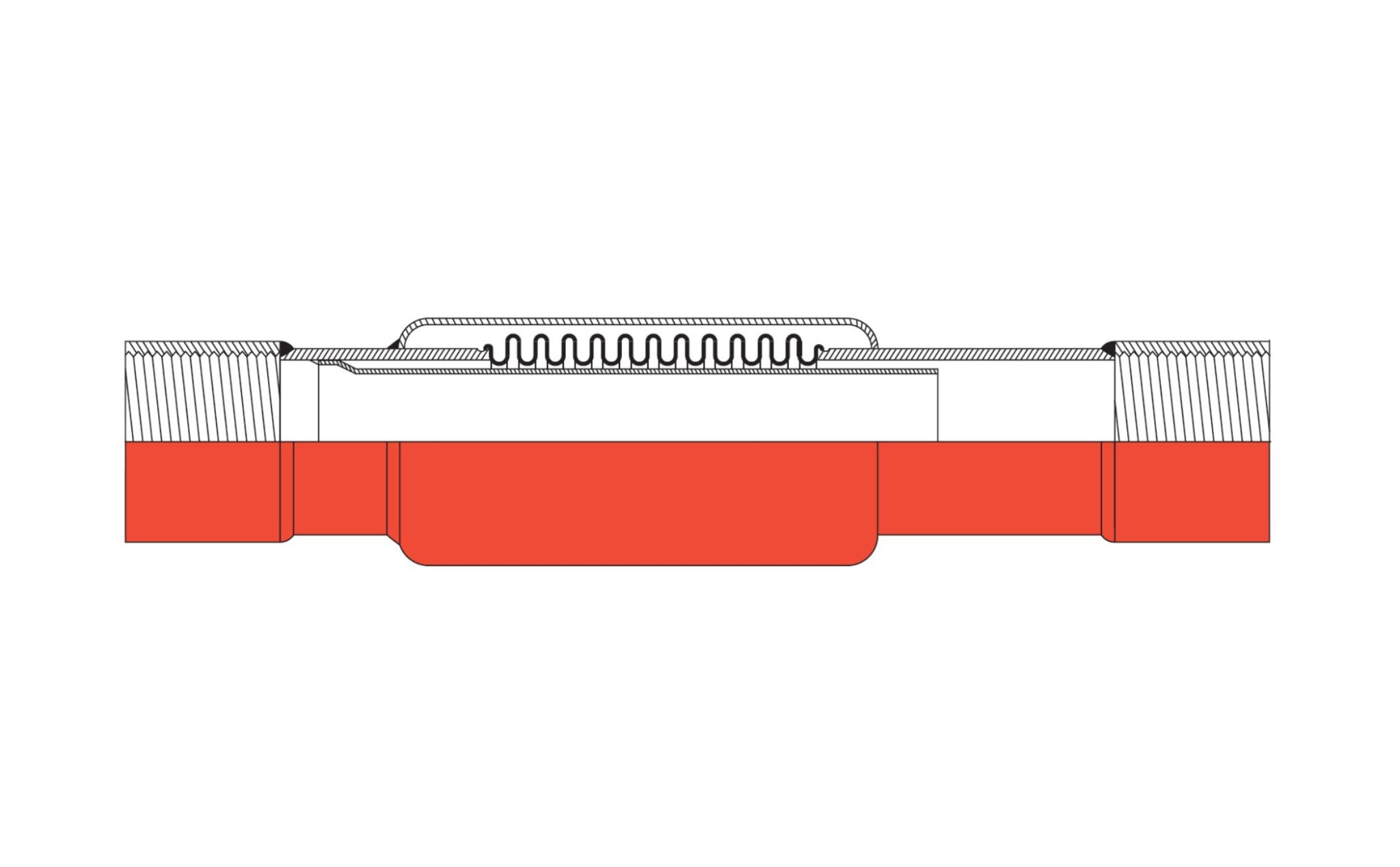

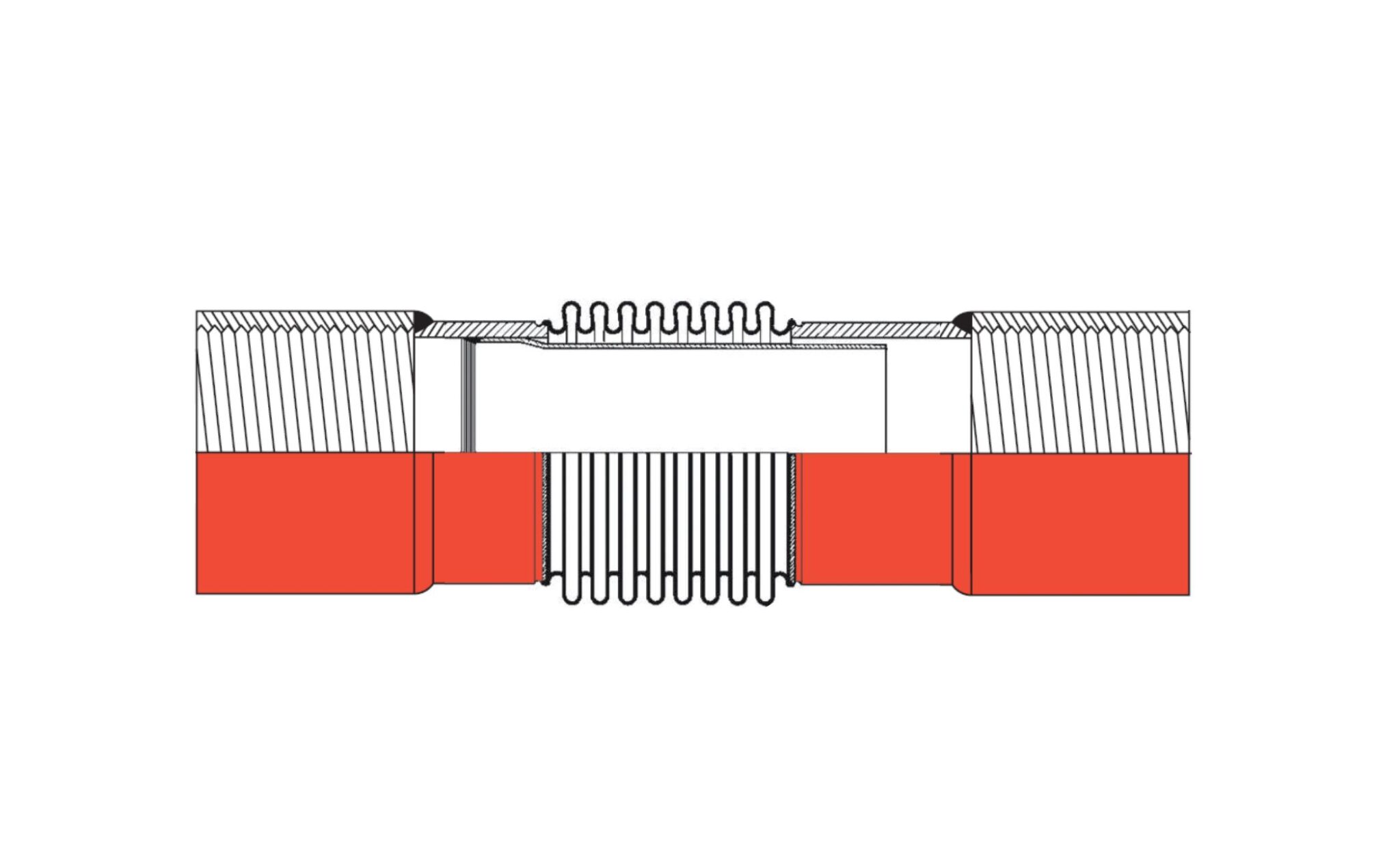

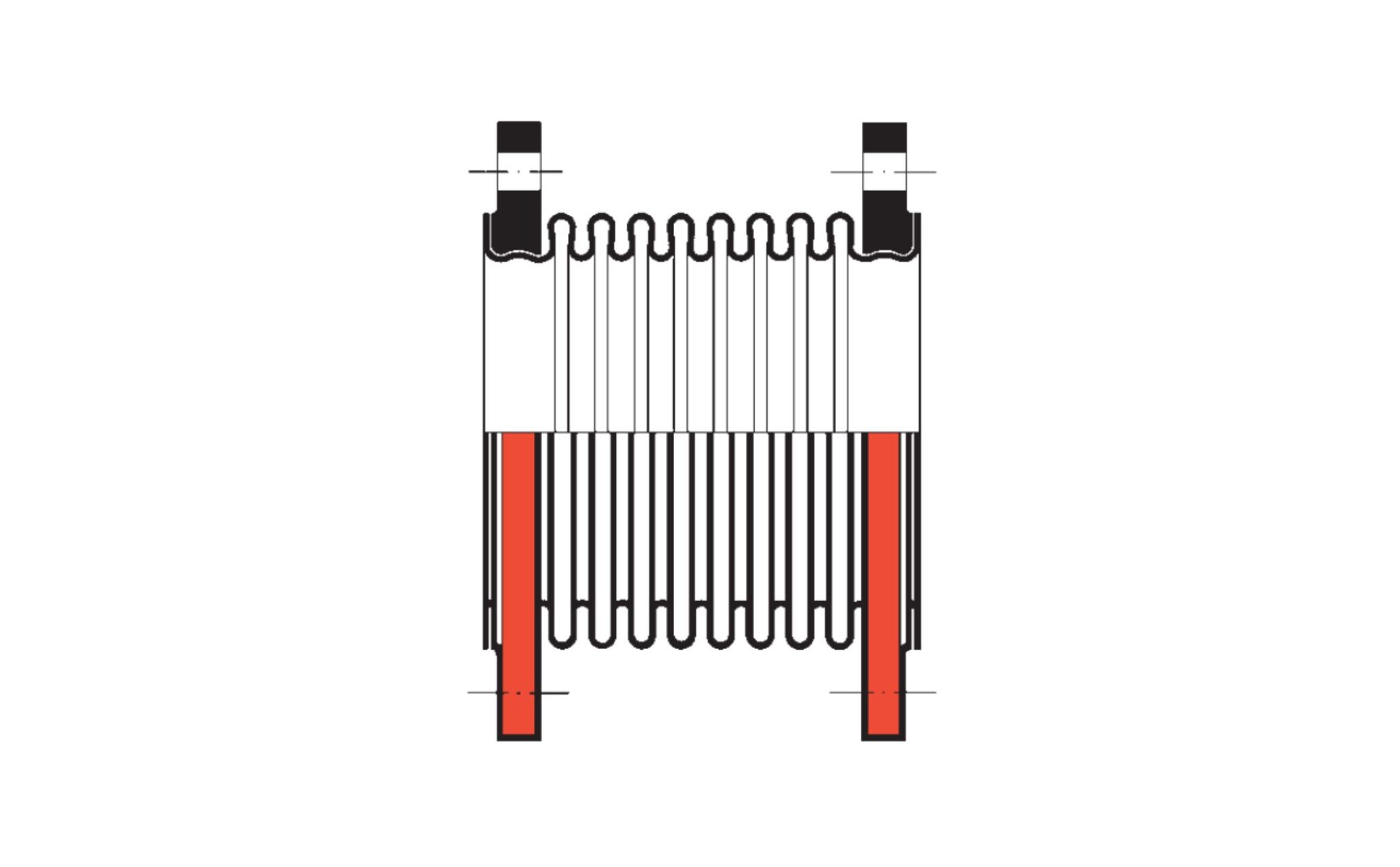

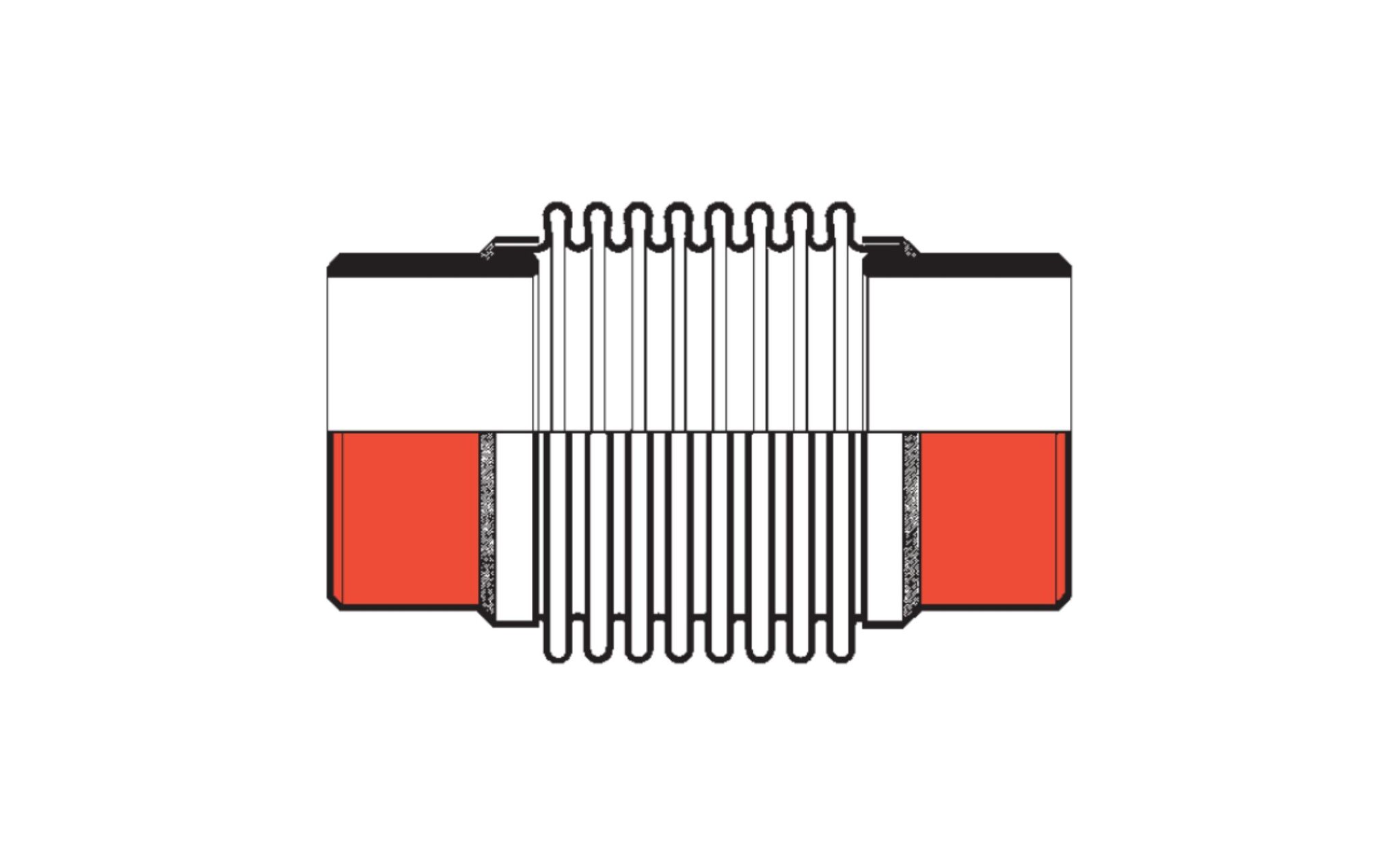

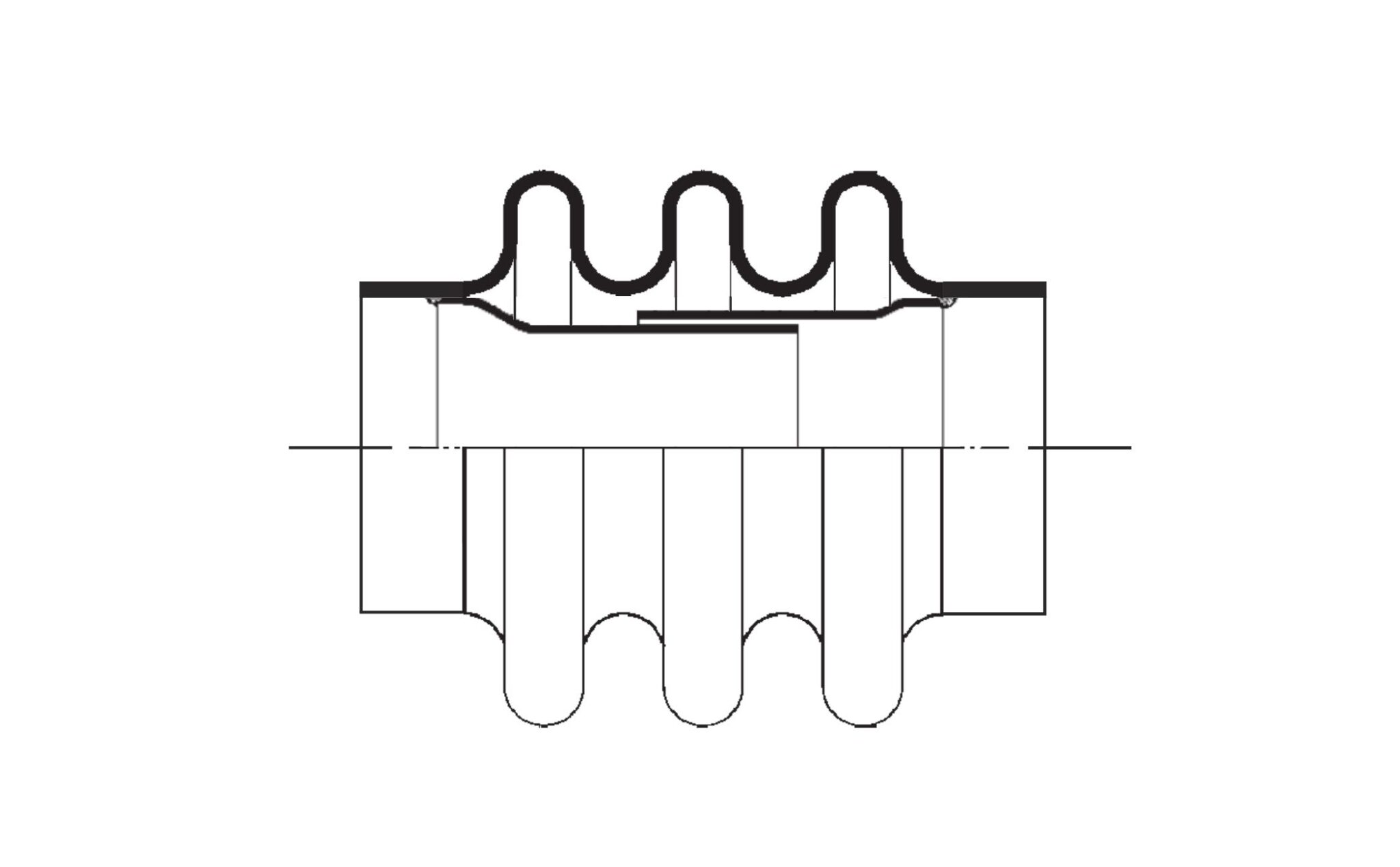

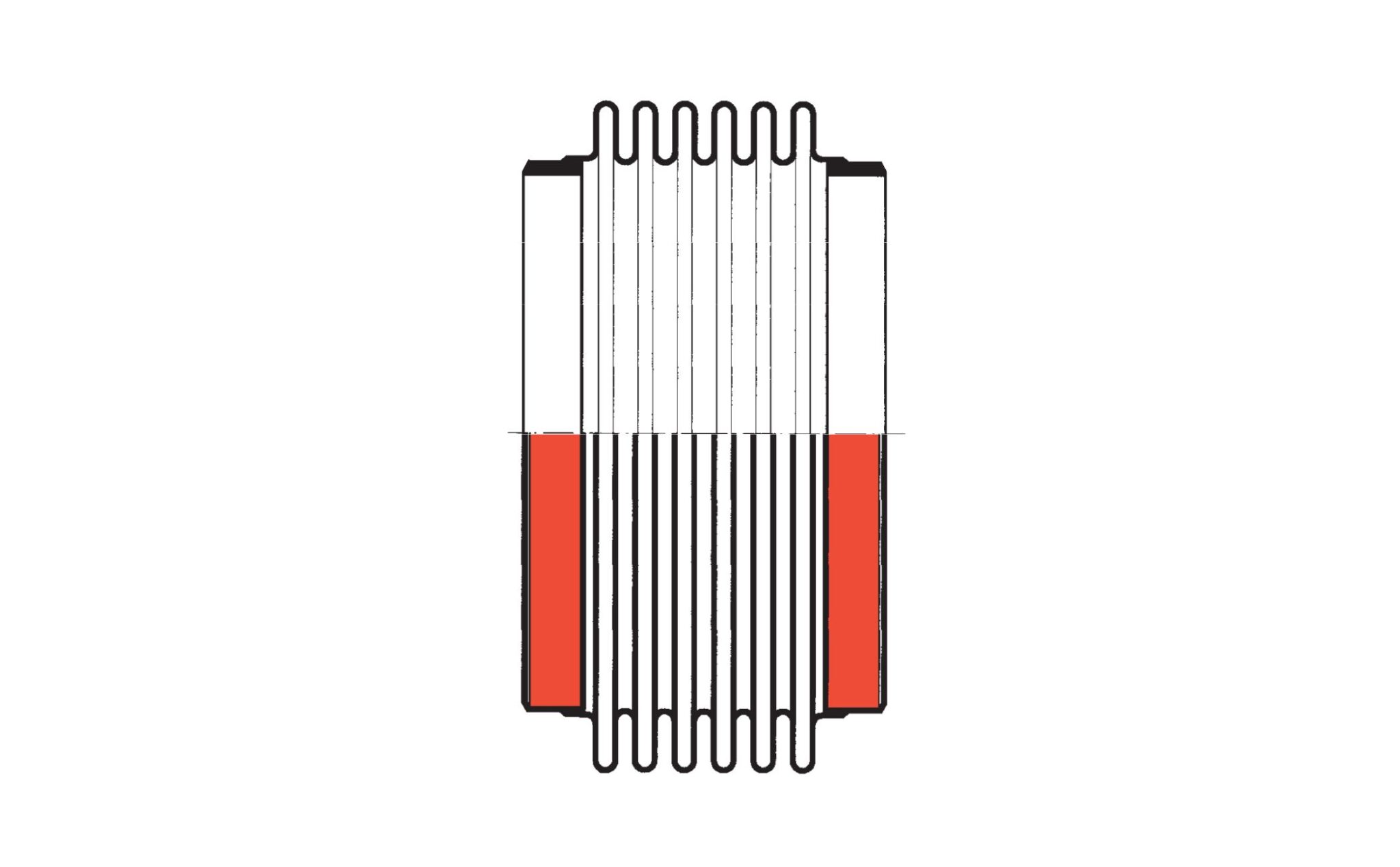

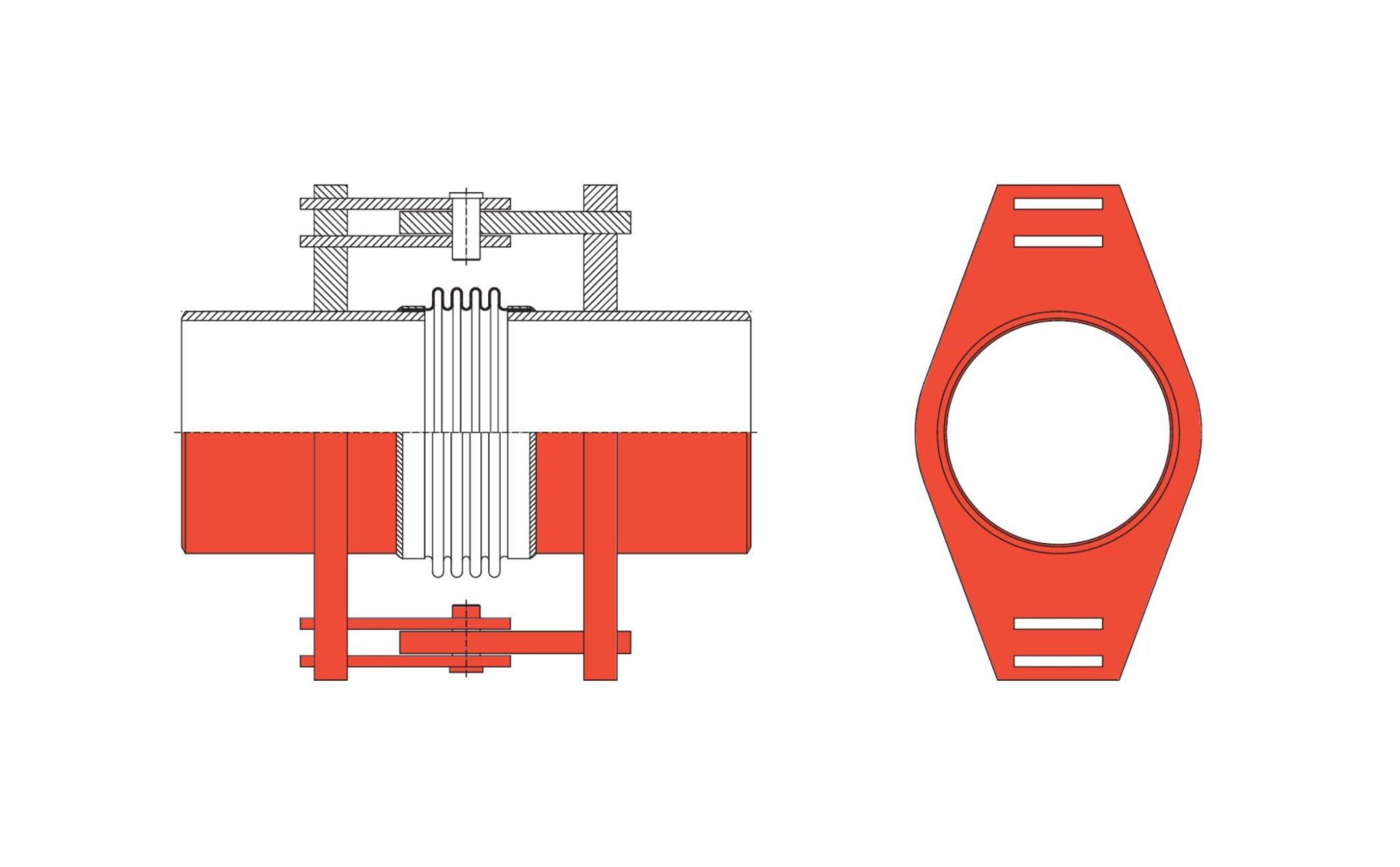

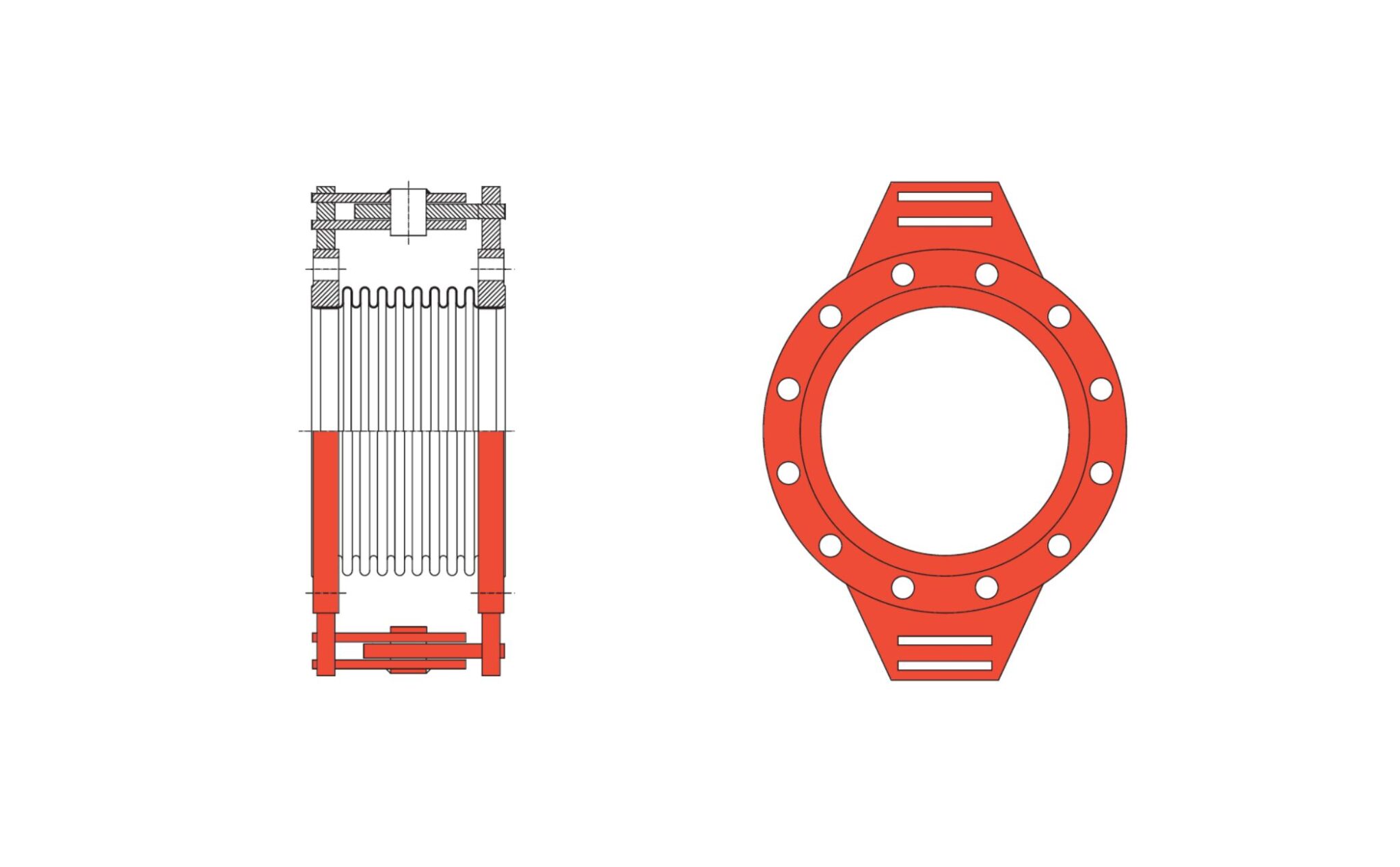

K Series

Low Pressure

Axial expansion expansion joints designed for residential and light industrial applications in heating, air‑conditioning, domestic hot water and low‑pressure steam systems. Compact construction with precision‑corrugated bellows.

✓ Pressure range: PN 16 bar (standard), also available PN 6, 10, 25

✓ Diameters: DN 12 to DN 150 mm with axial movements of ±30 mm

✓ Connections: Welded, threaded (gas) or flanged depending on the application; optional inner sleeve

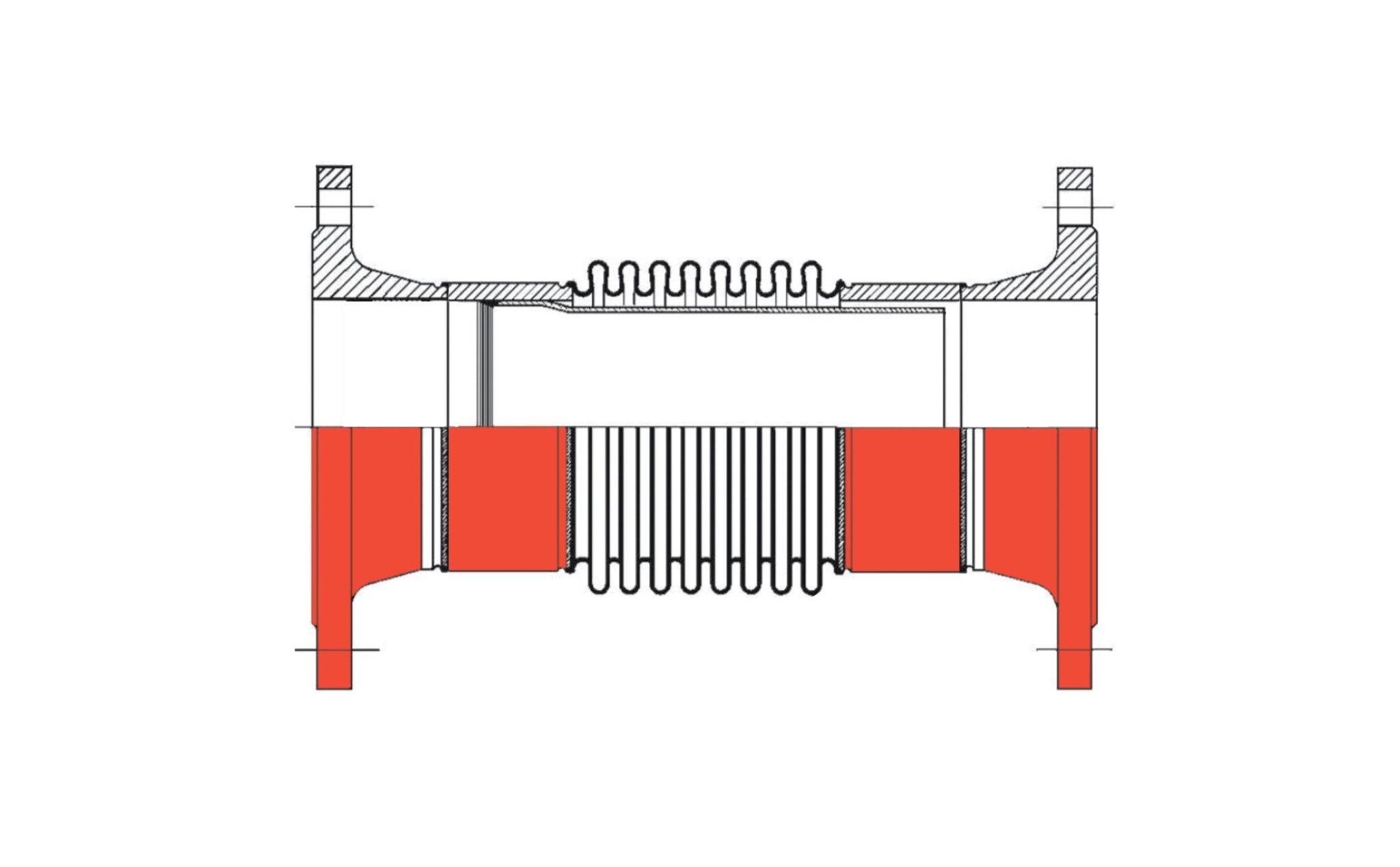

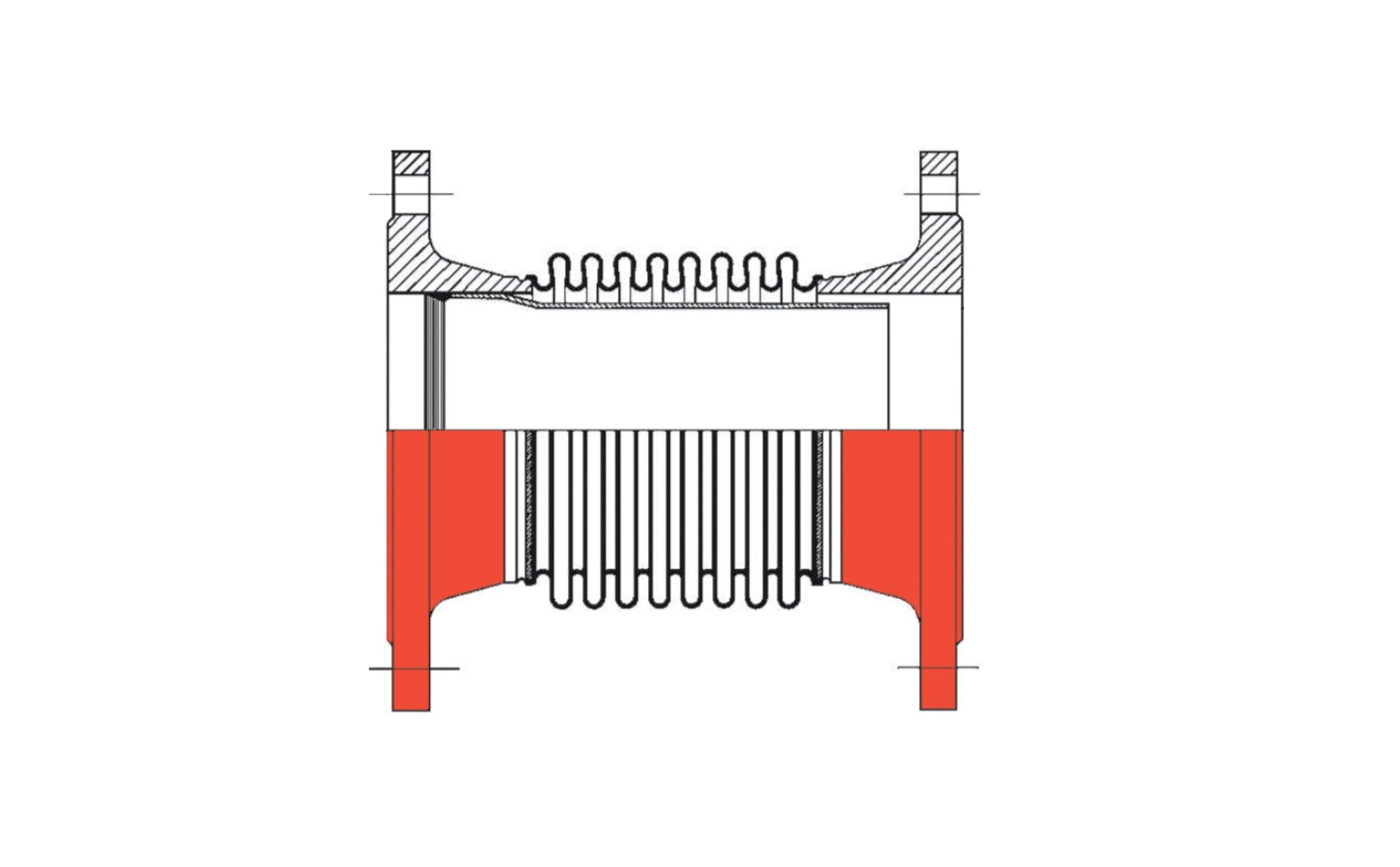

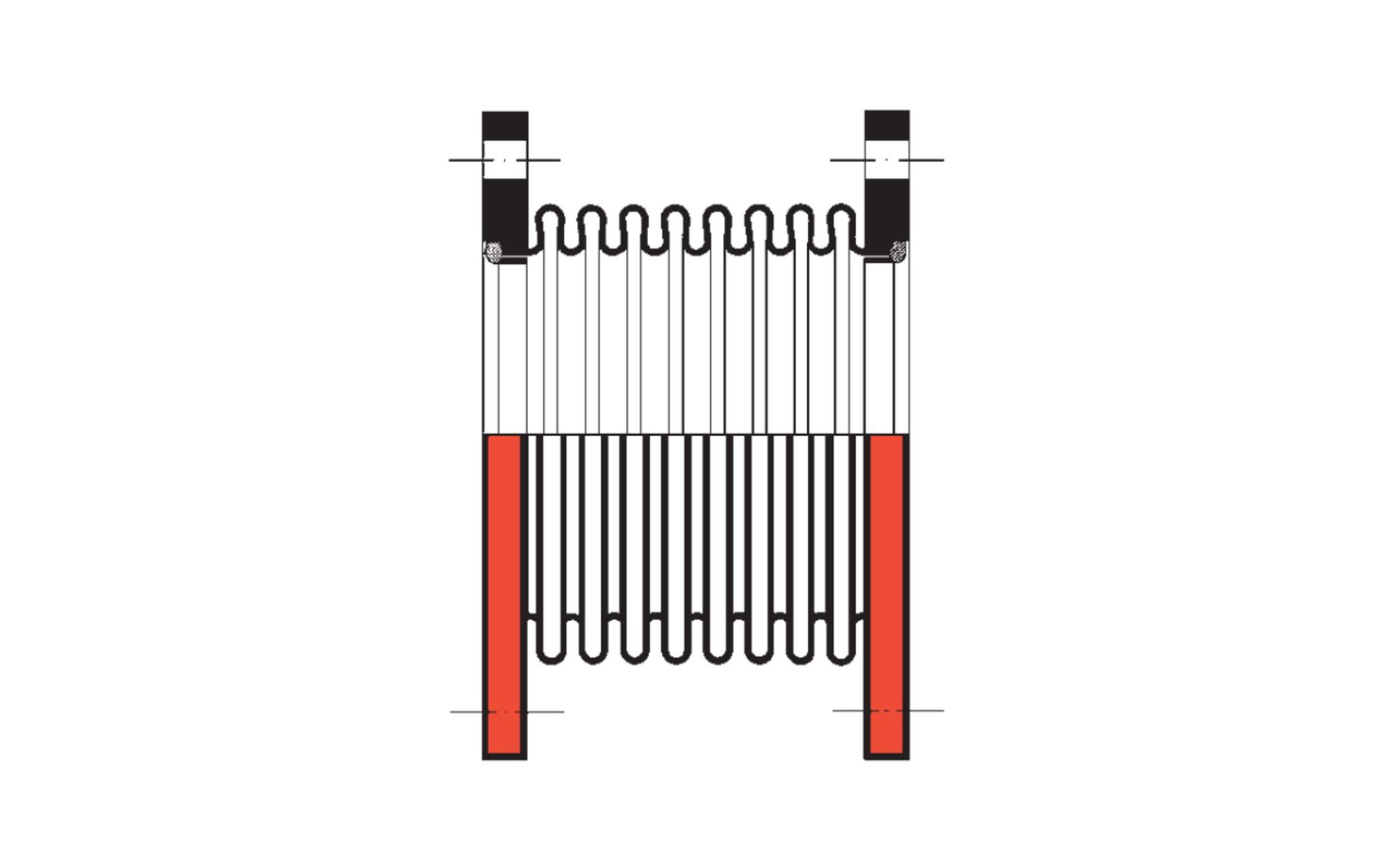

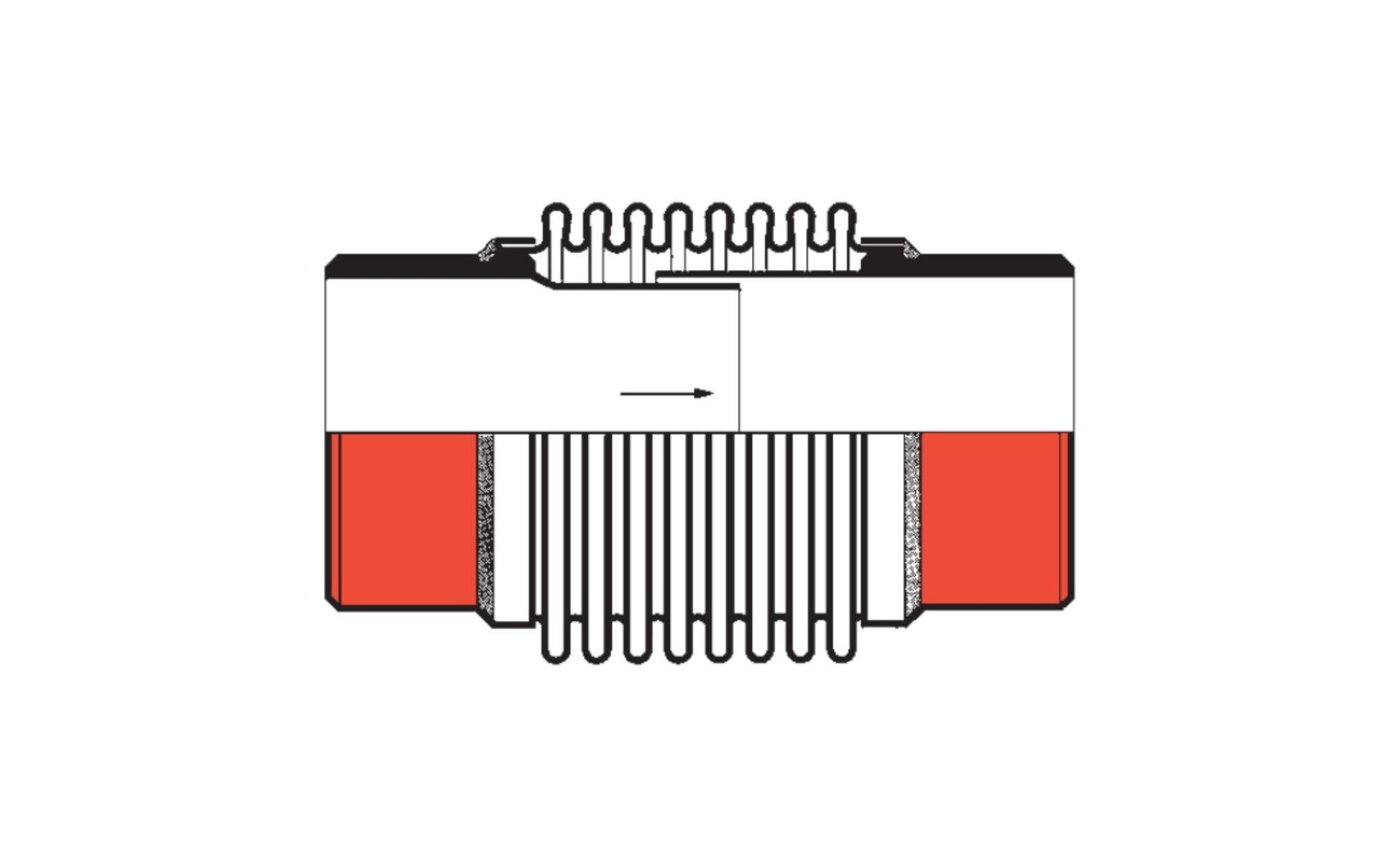

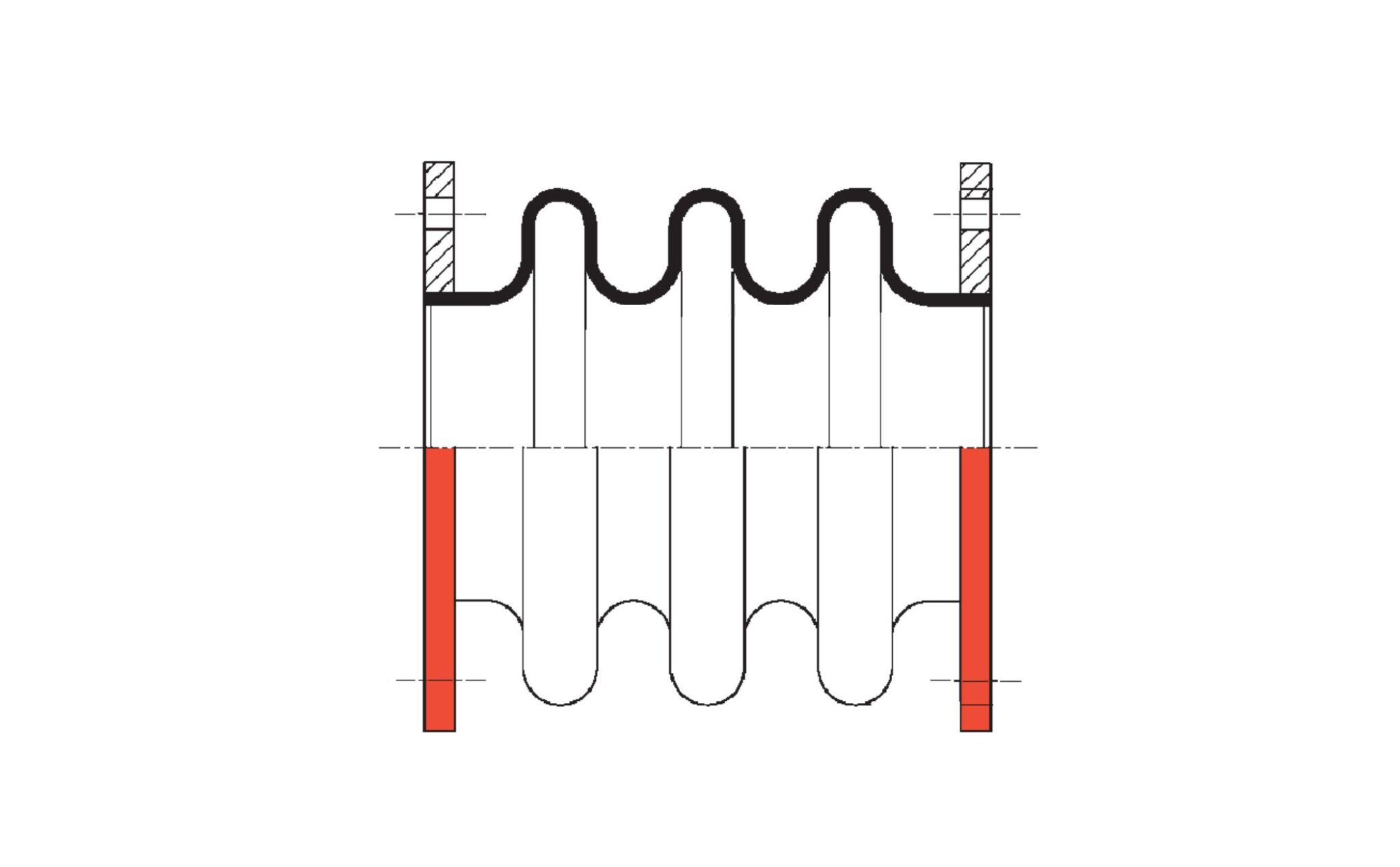

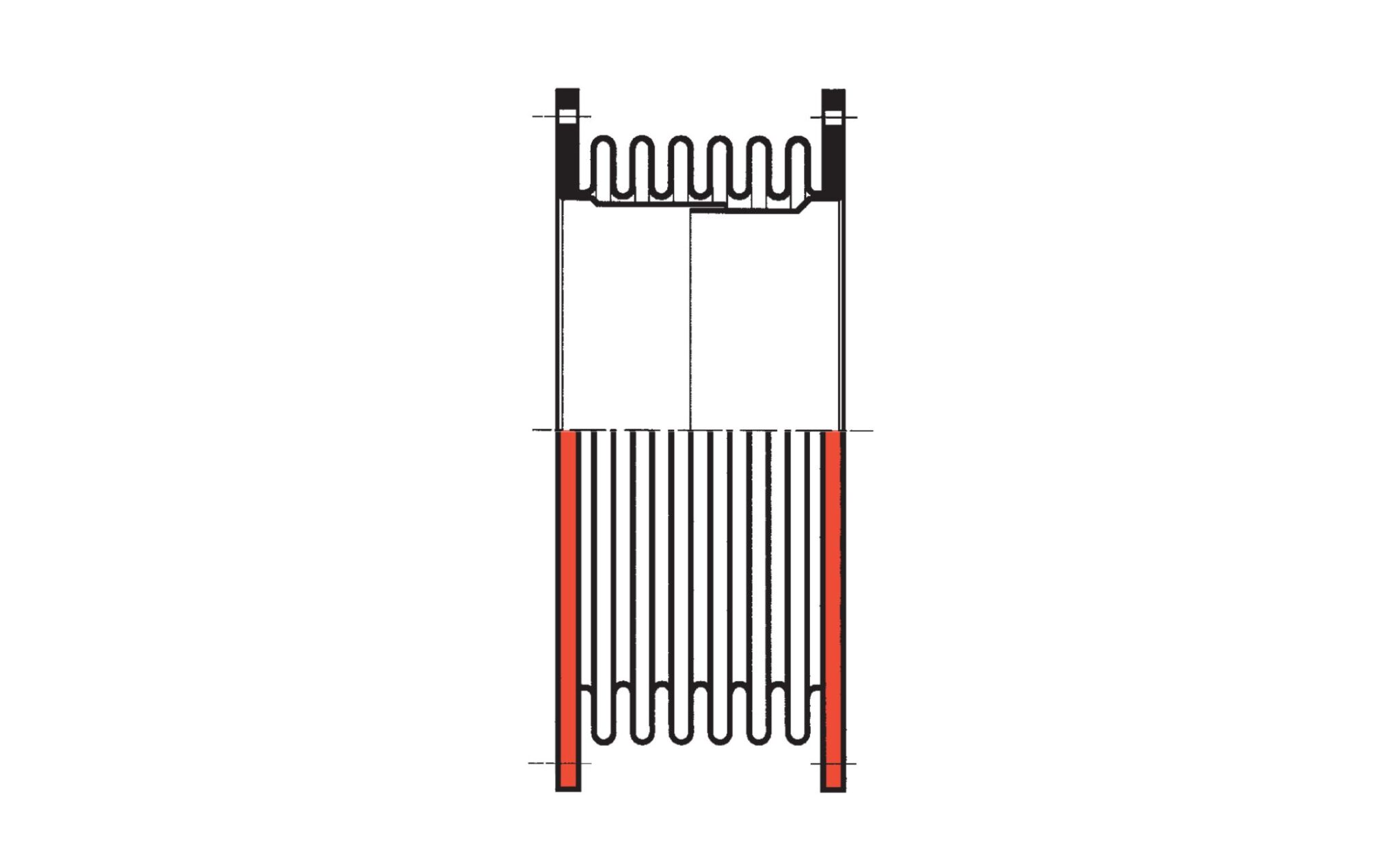

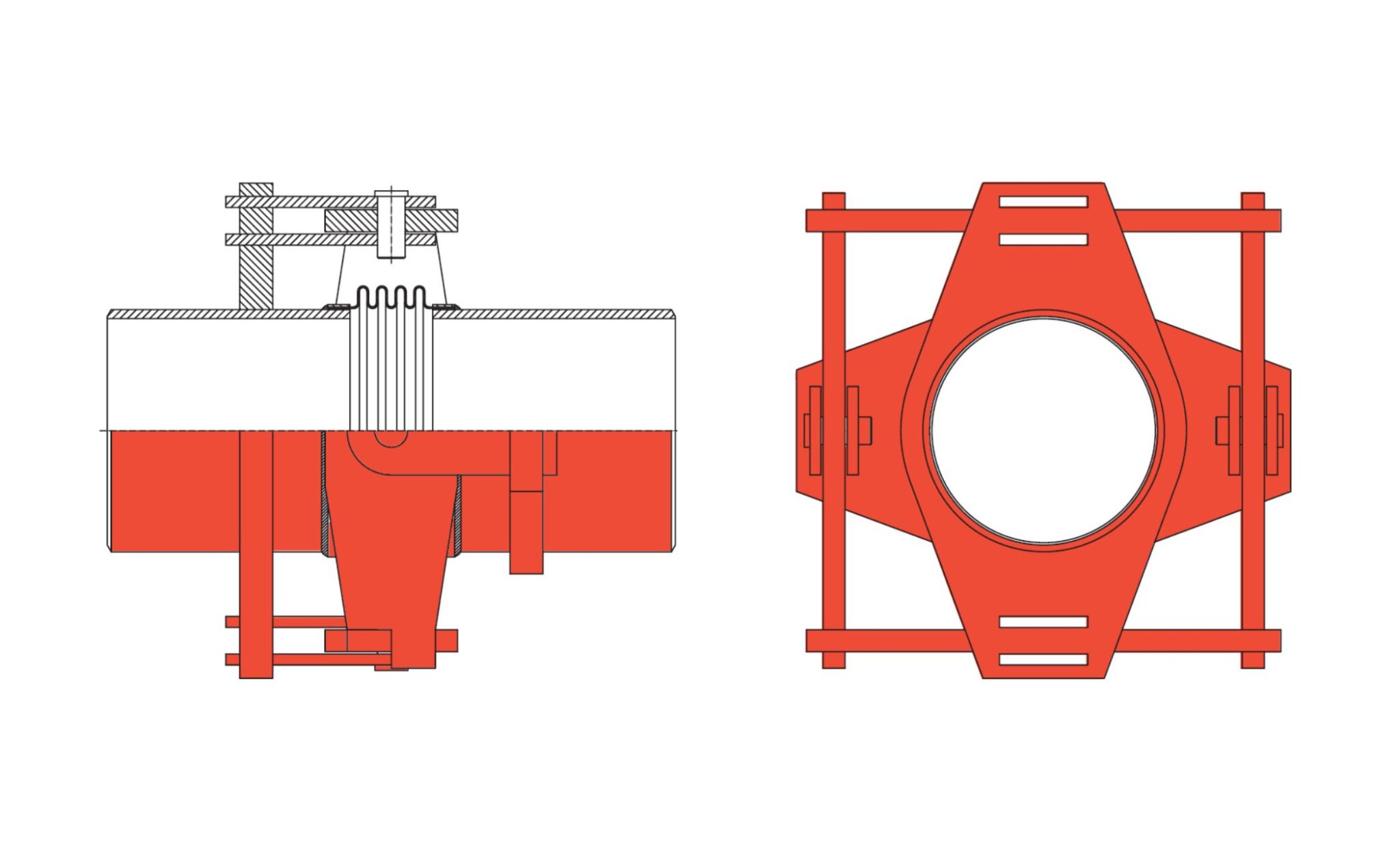

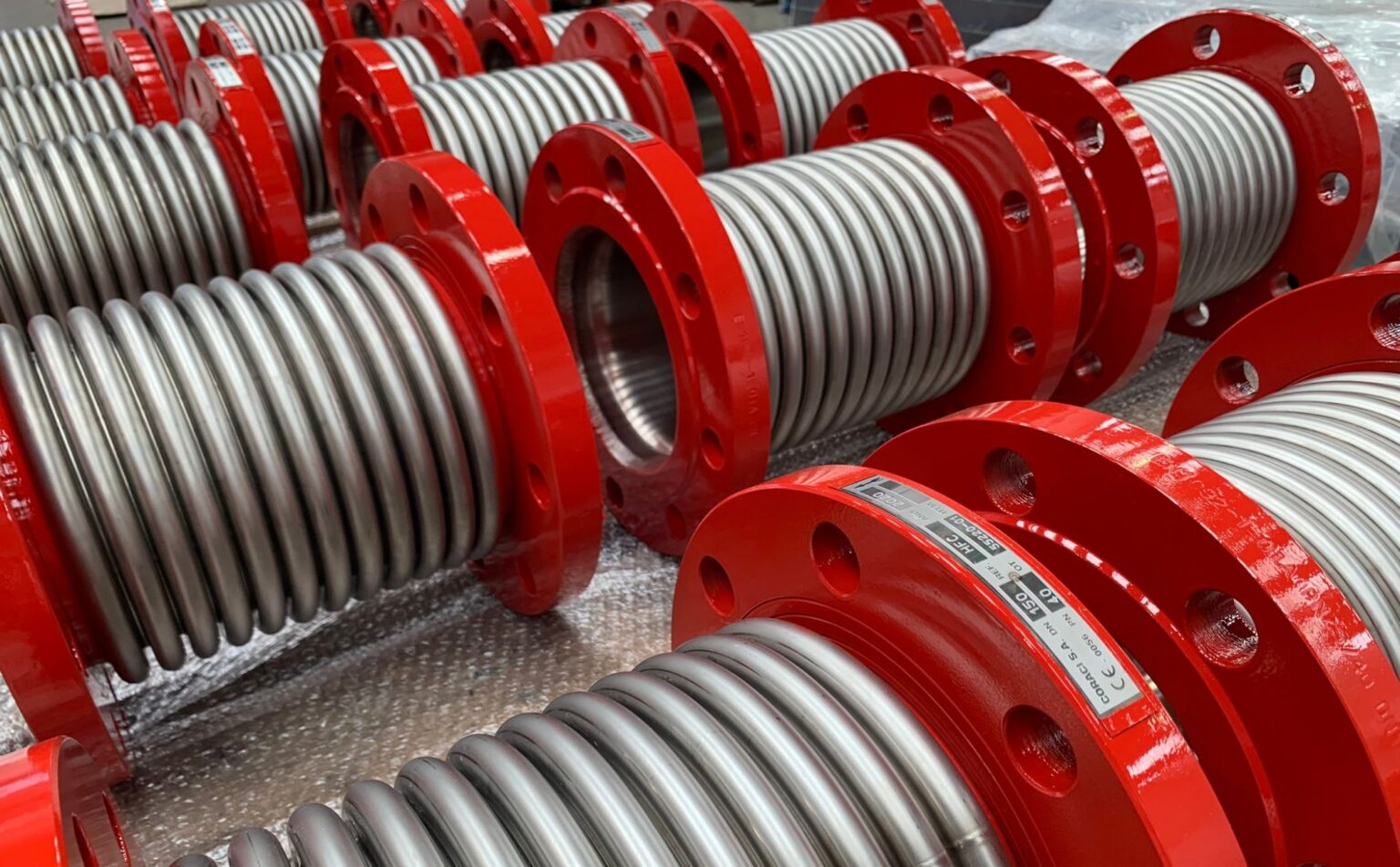

H Series

High Pressure - Axial Movement

High‑performance multipurpose expansion joints for demanding industrial services. Robust design with multi‑ply bellows capable of absorbing extreme pressures and temperatures in critical plants.

✓ Pressure range: PN 6 to PN 150 bar, adaptable to customer specifications.

✓ Temperature range: up to 750ºC

✓ Diameters: DN 40 to DN 6,000+ mm; variable axial displacements depending on pressure and material

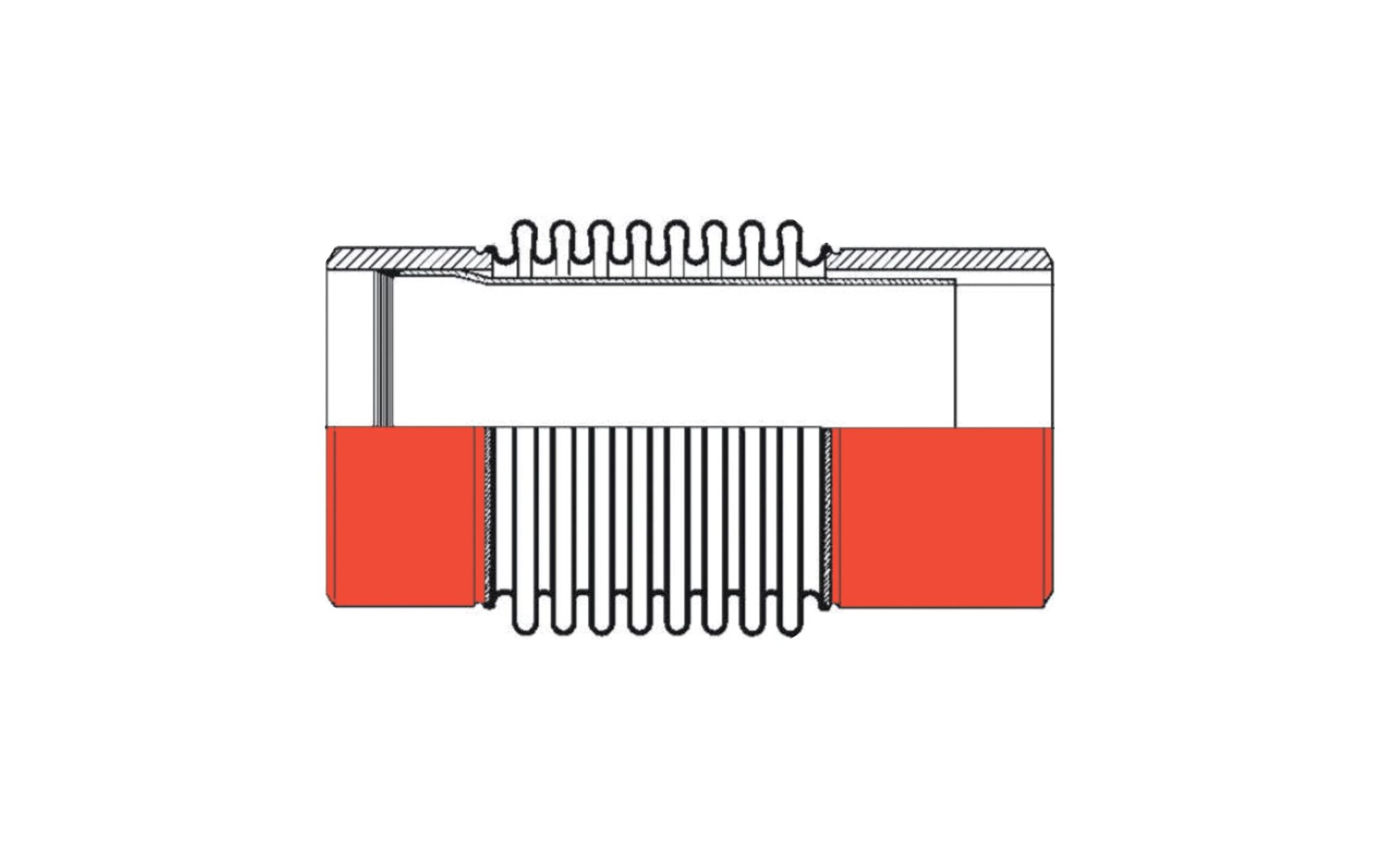

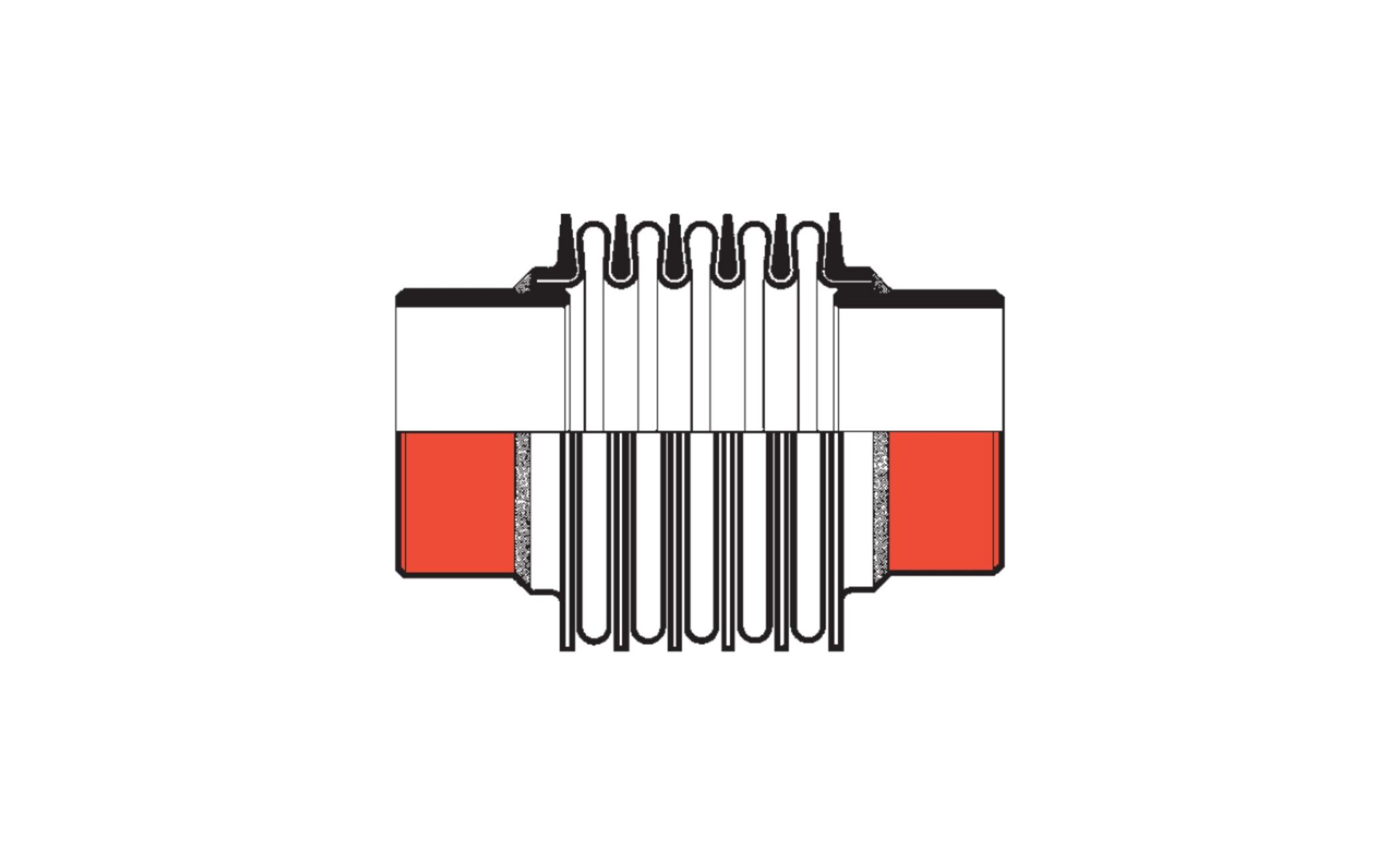

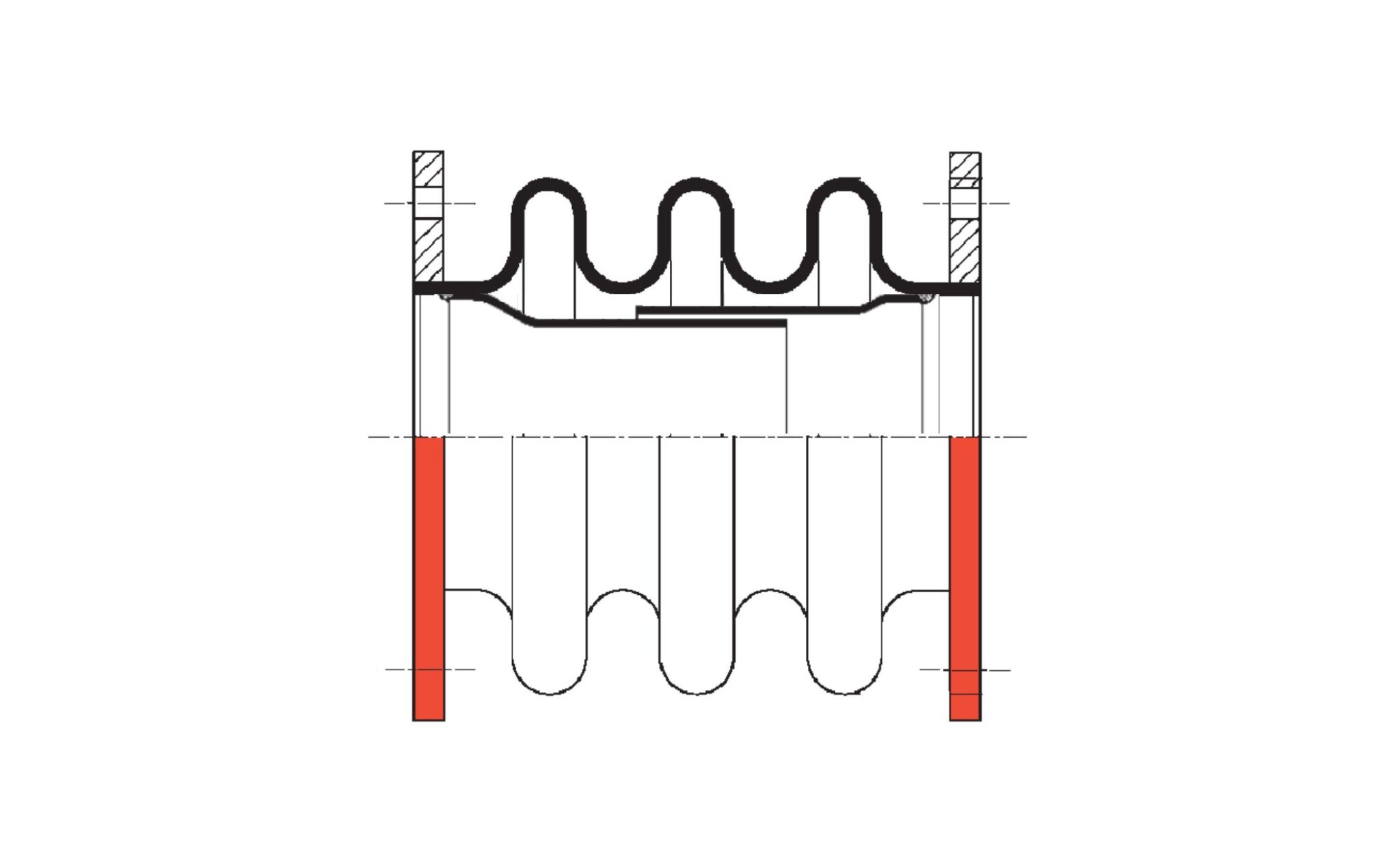

G Series

Heavy Boilerwork

Expansion joints with giant corrugations specifically developed for severe heavy‑boilerwork applications, heat exchangers, turbines and power‑generation plants. Bellows with a high deformation capacity.

✓ Especially suitable for aggressive fluids, blast‑furnace gases and corrosive fumes

✓ Diameters: DN 100 to DN 3,000+ mm; pressure adjustable according to material and thickness

✓ Extended service life: designed for extreme temperature and pressure cycles in continuous operation

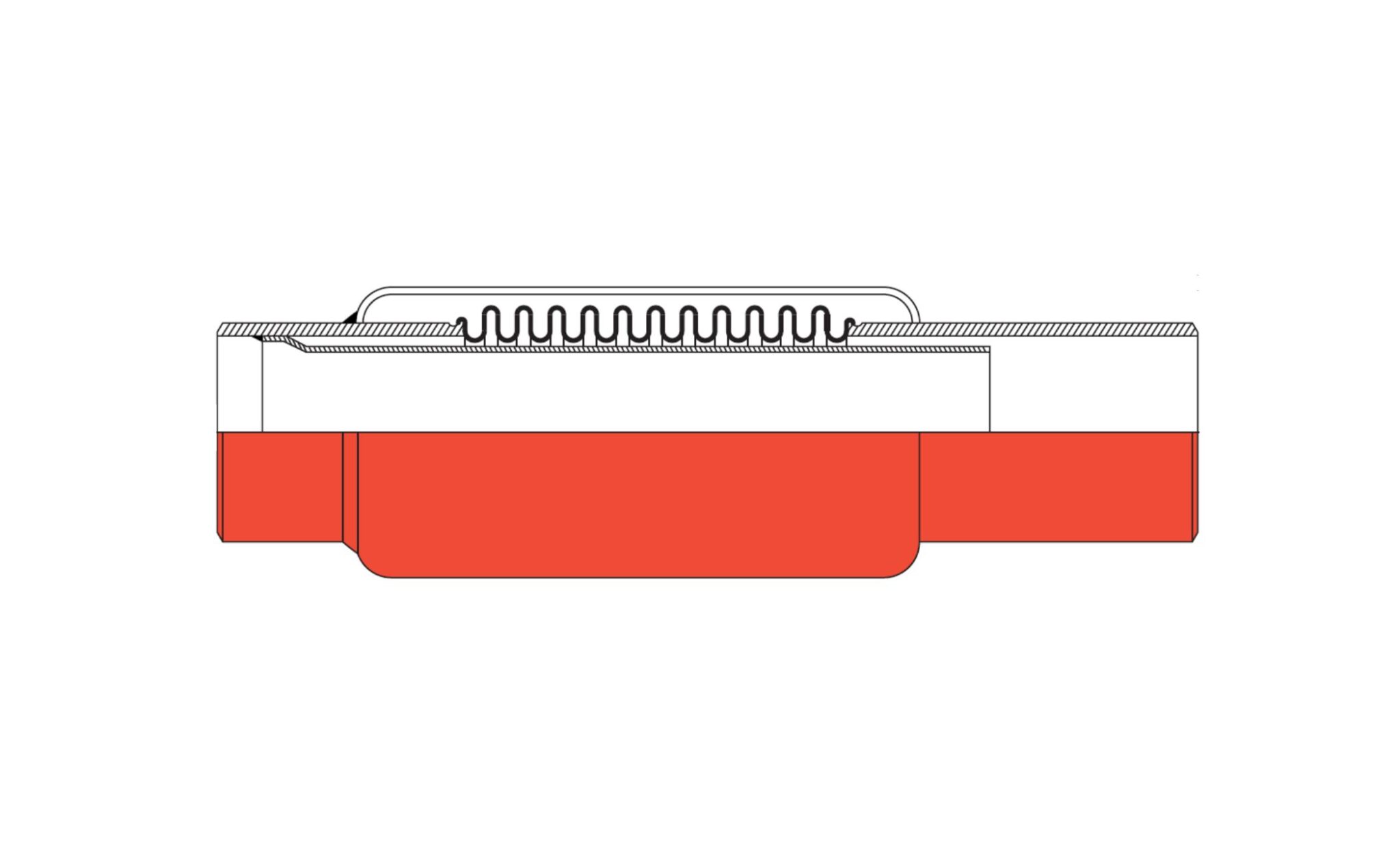

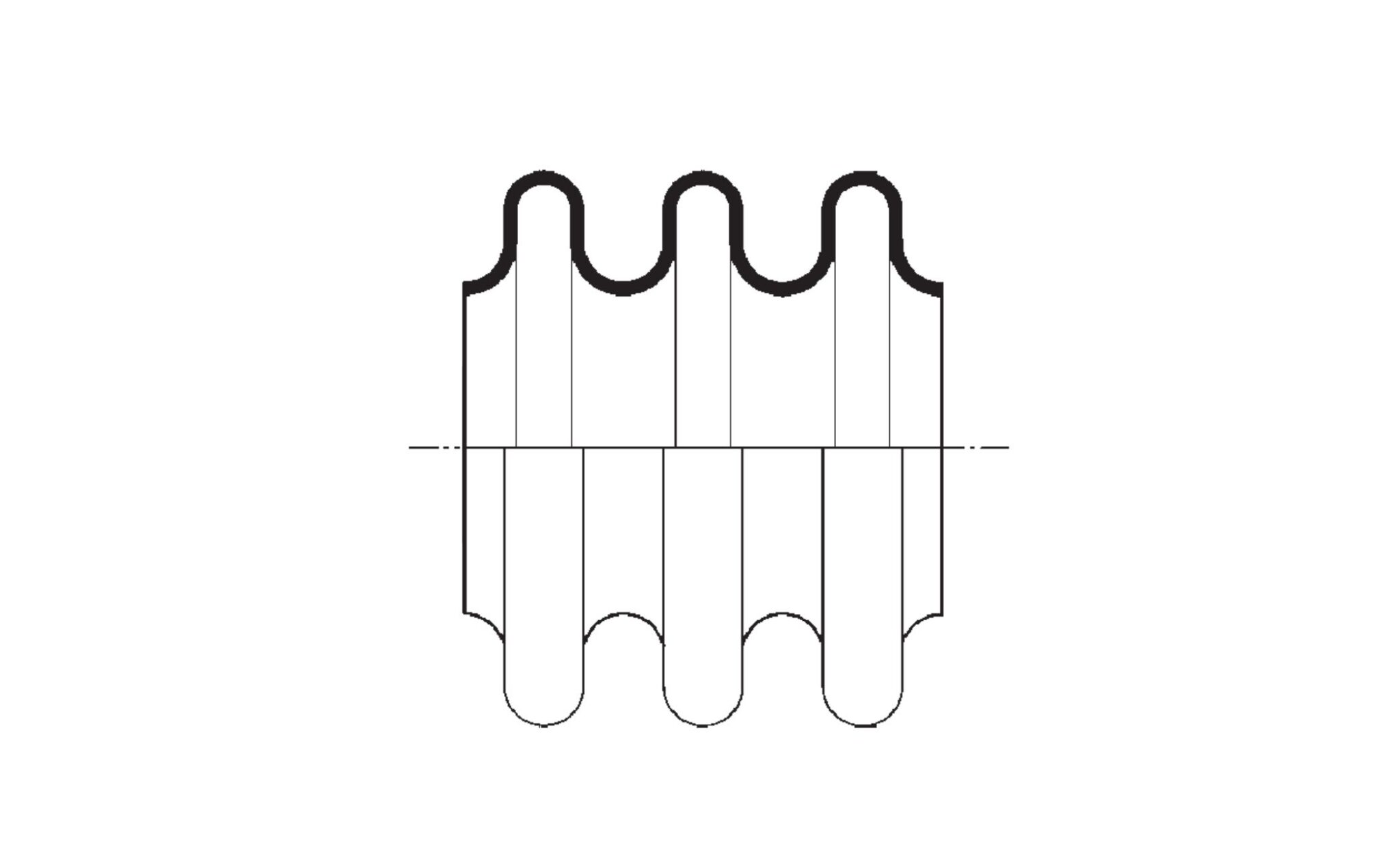

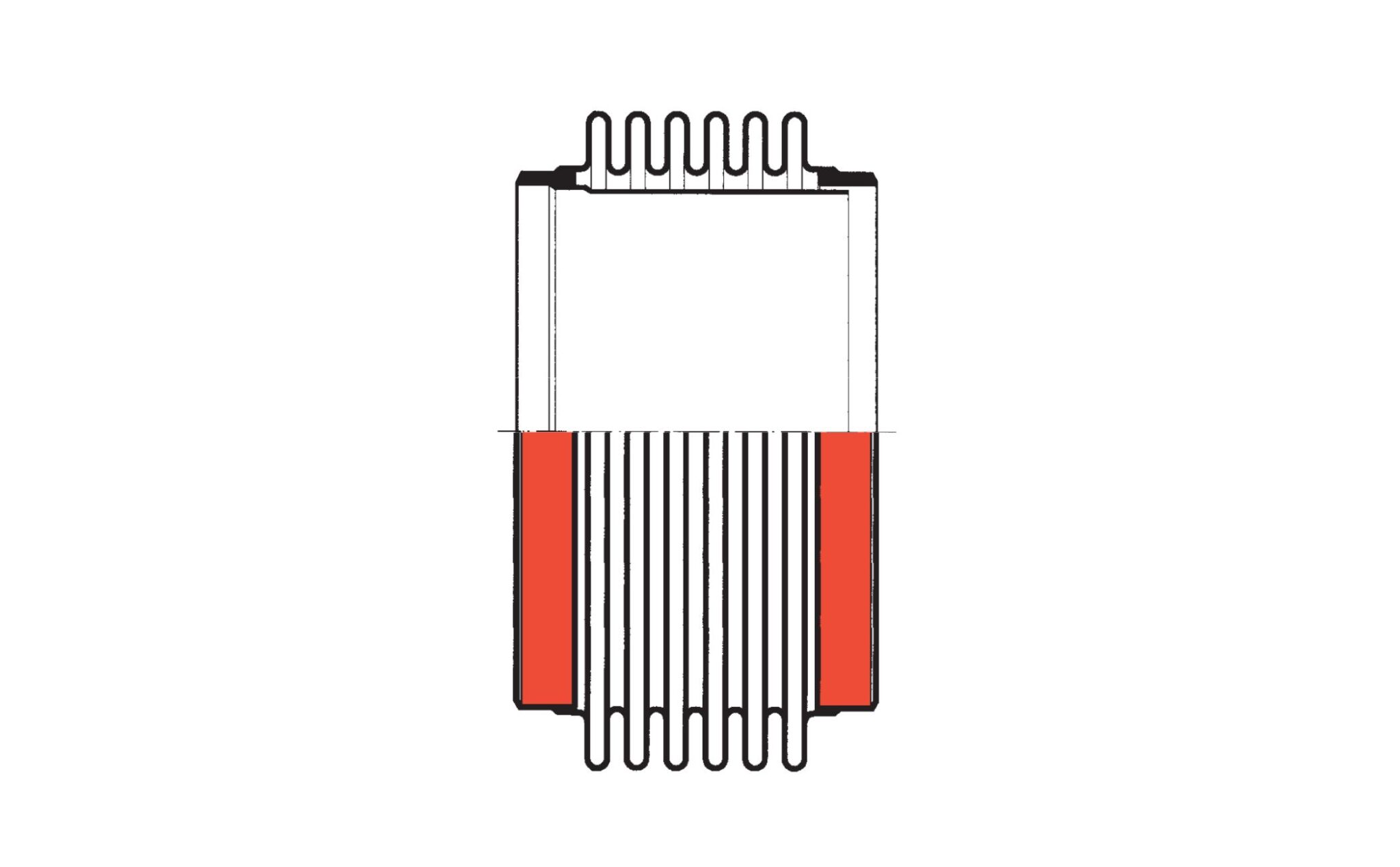

C2000 Series

For Large Diameters

Proprietary CORACI solution for large diameters above DN 1,000 mm. Developed with advanced engineering and FEA analysis for special large‑scale industrial infrastructure projects.

(Fuelle monocapa para ductos)

✓ Range: DN 1,000 to DN 6,000+ mm (customizable according to project)

✓ Pressure: PN 2.5 to 16 bar standard; adaptable to specific customer requirements

✓ Ideal for large ducts: Cement plants, steel mills, large thermal power plants, ACC…

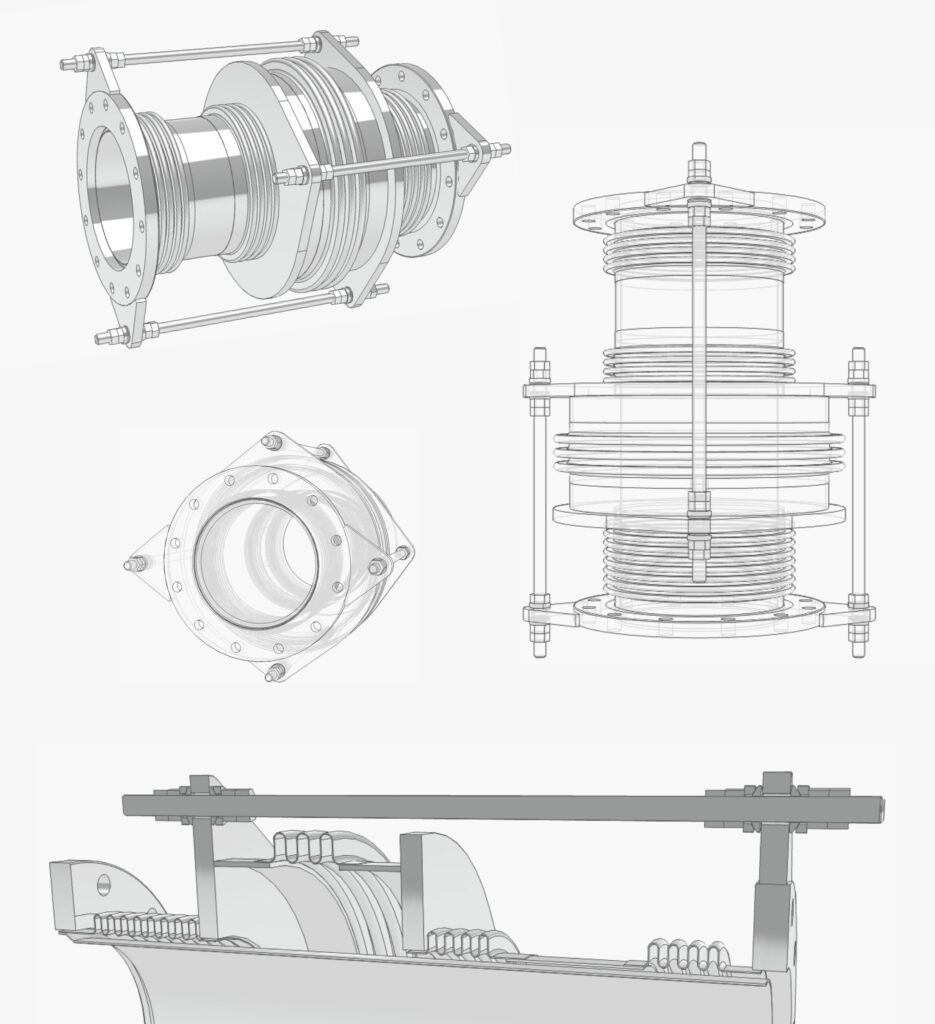

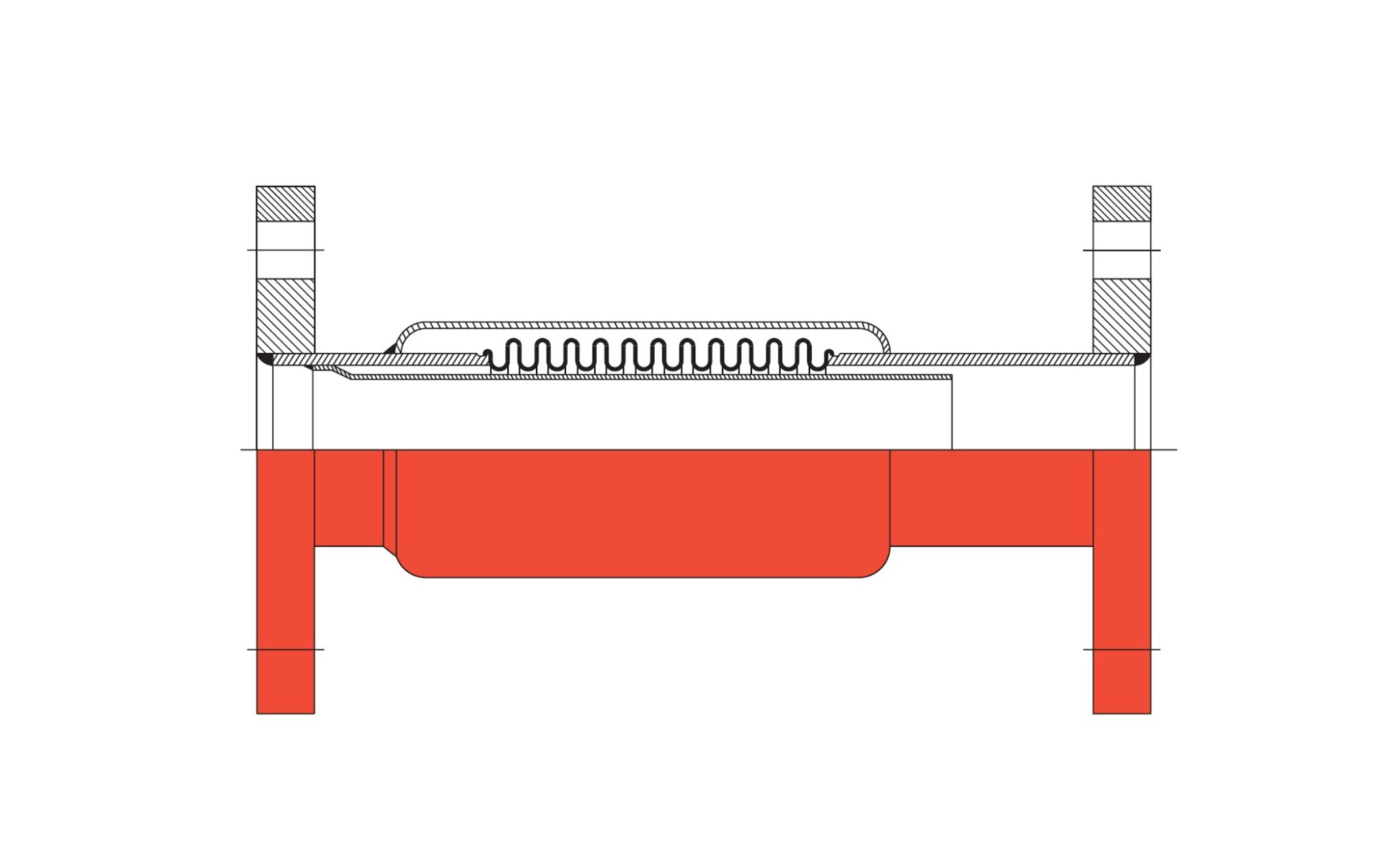

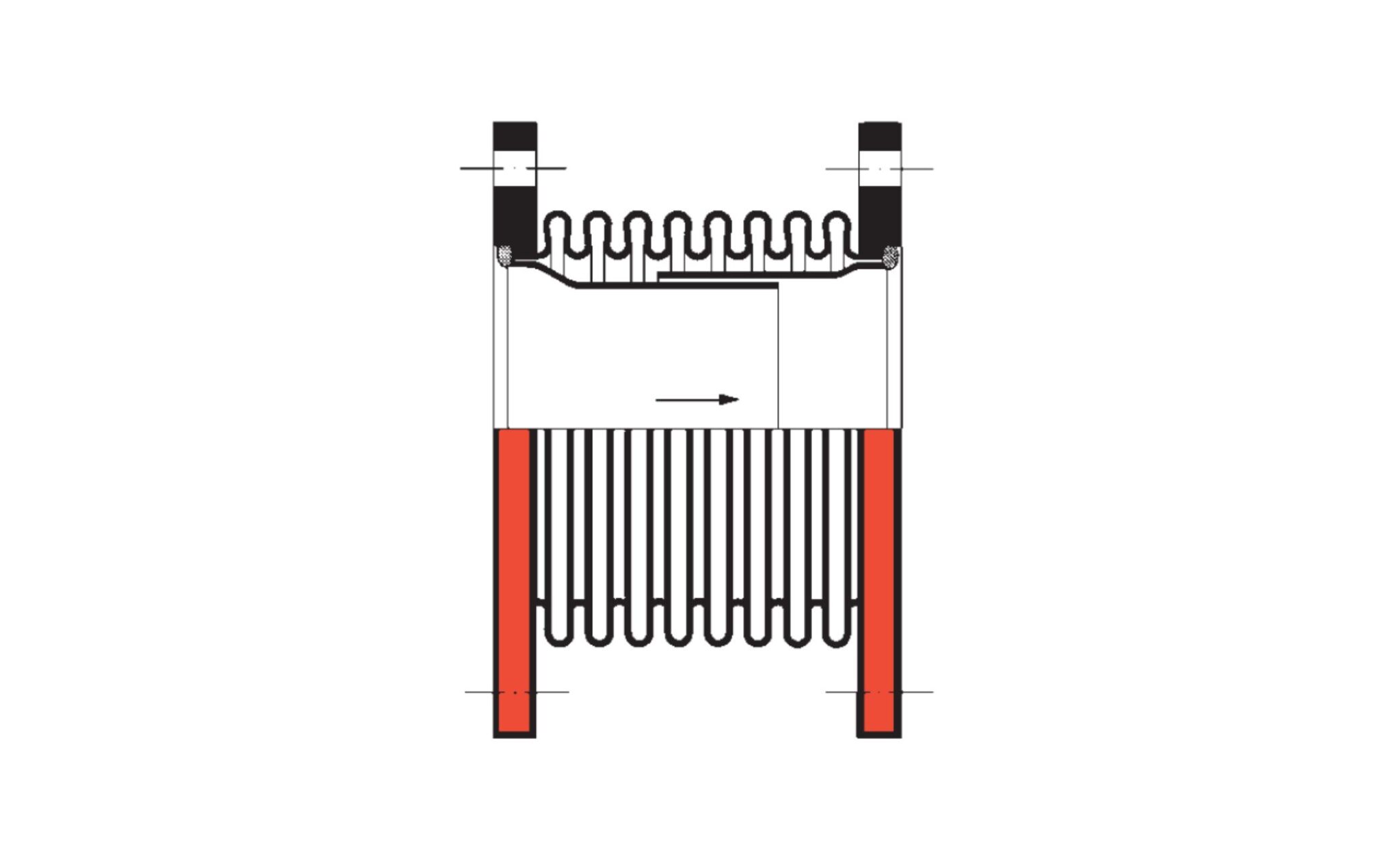

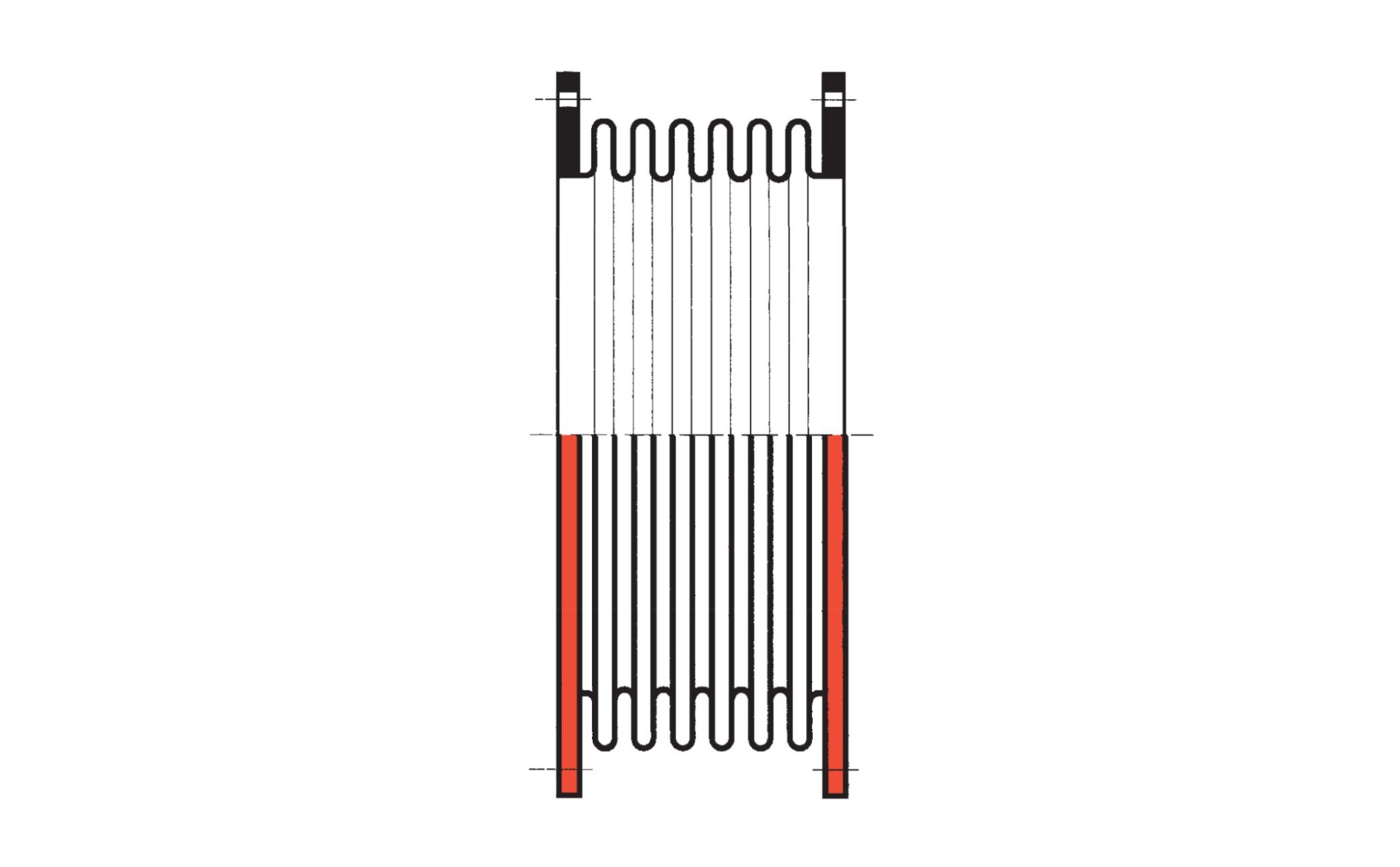

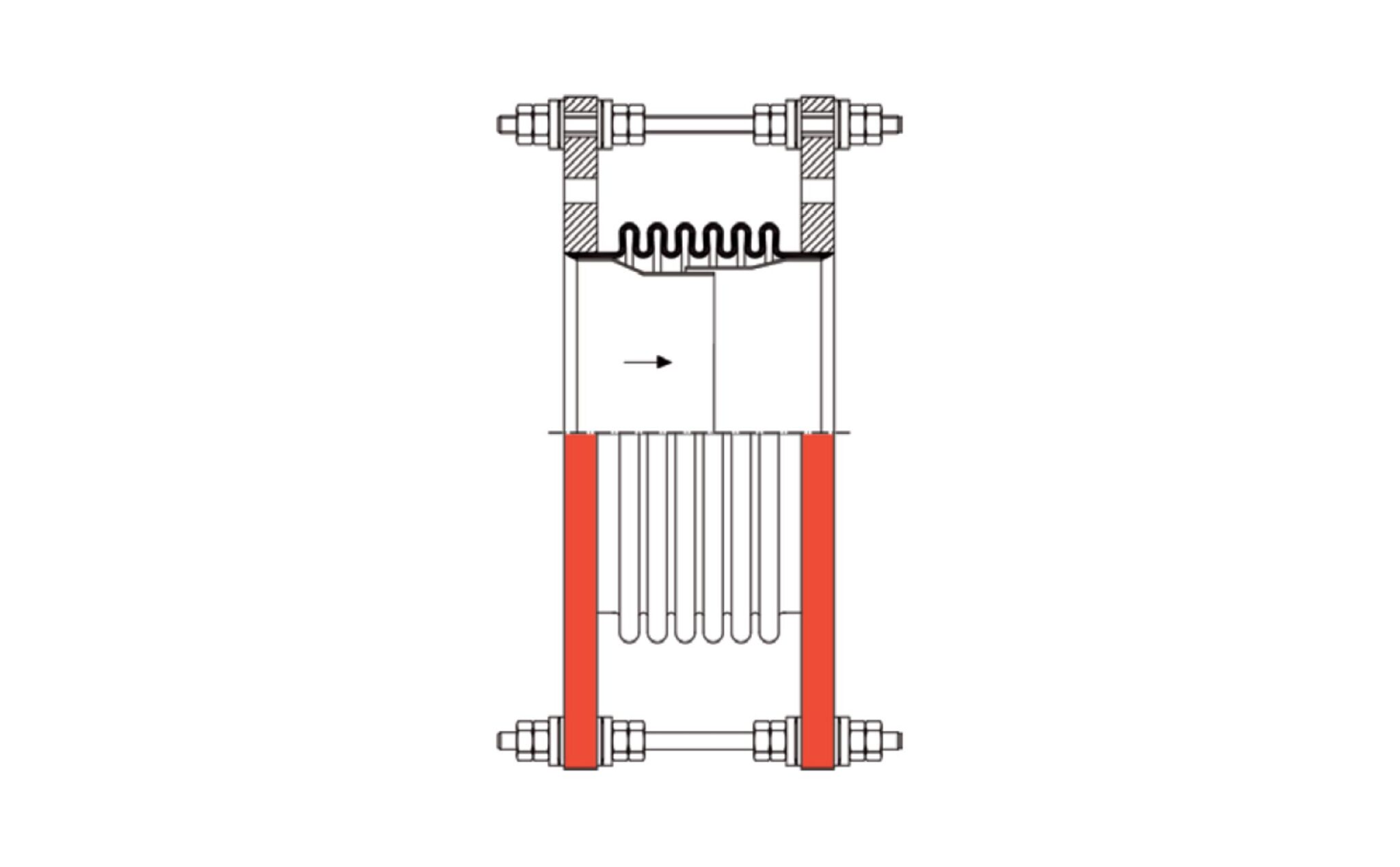

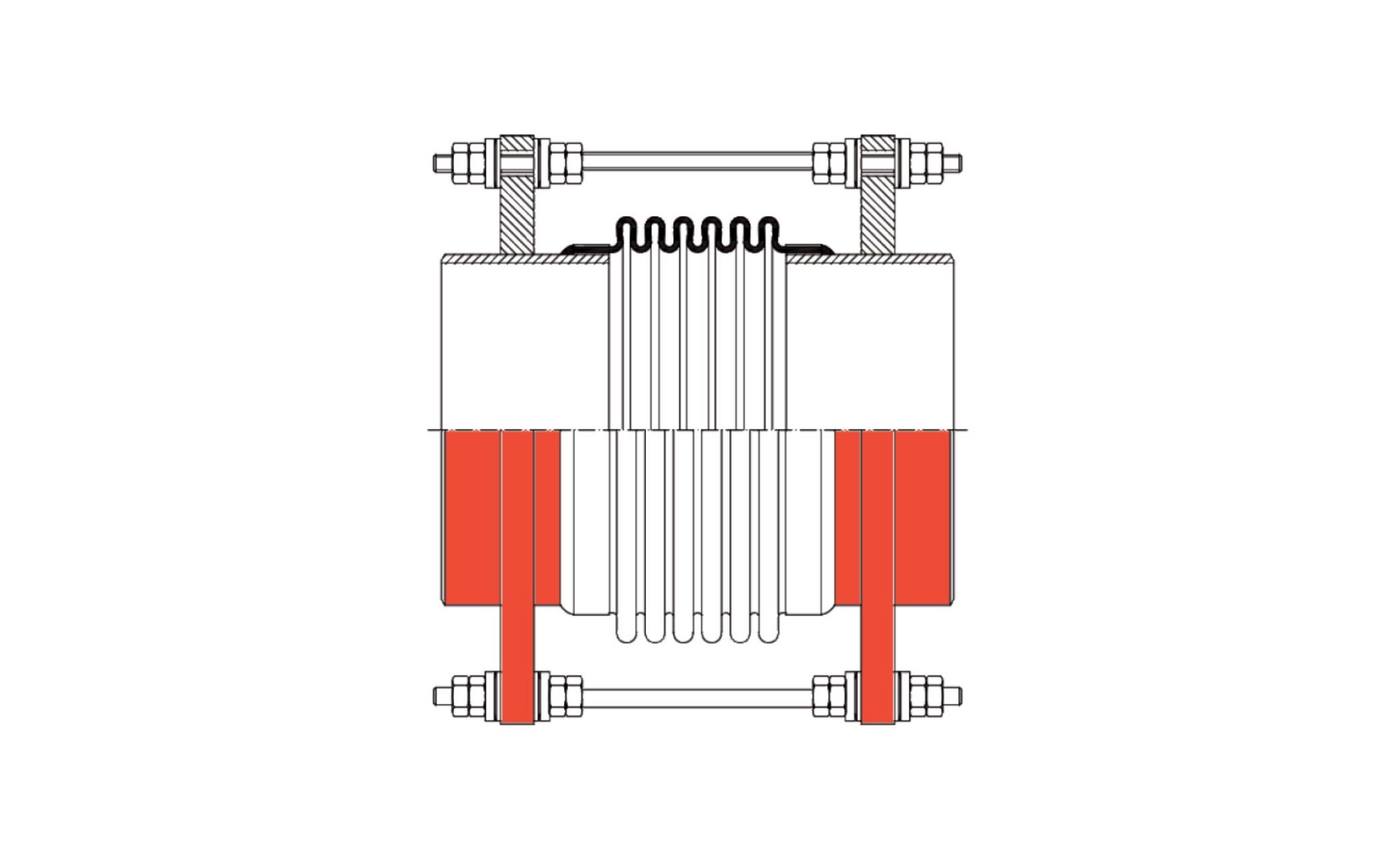

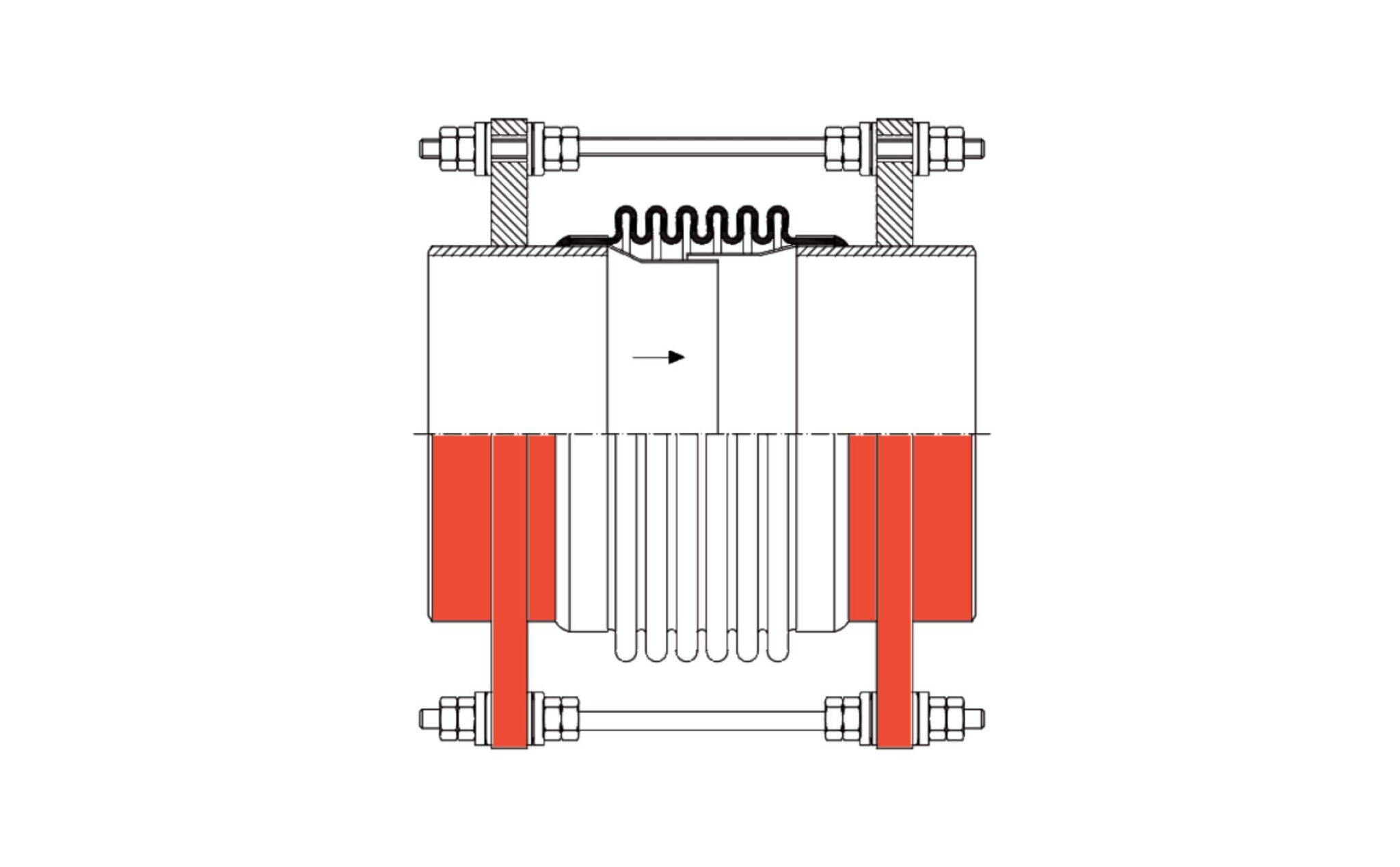

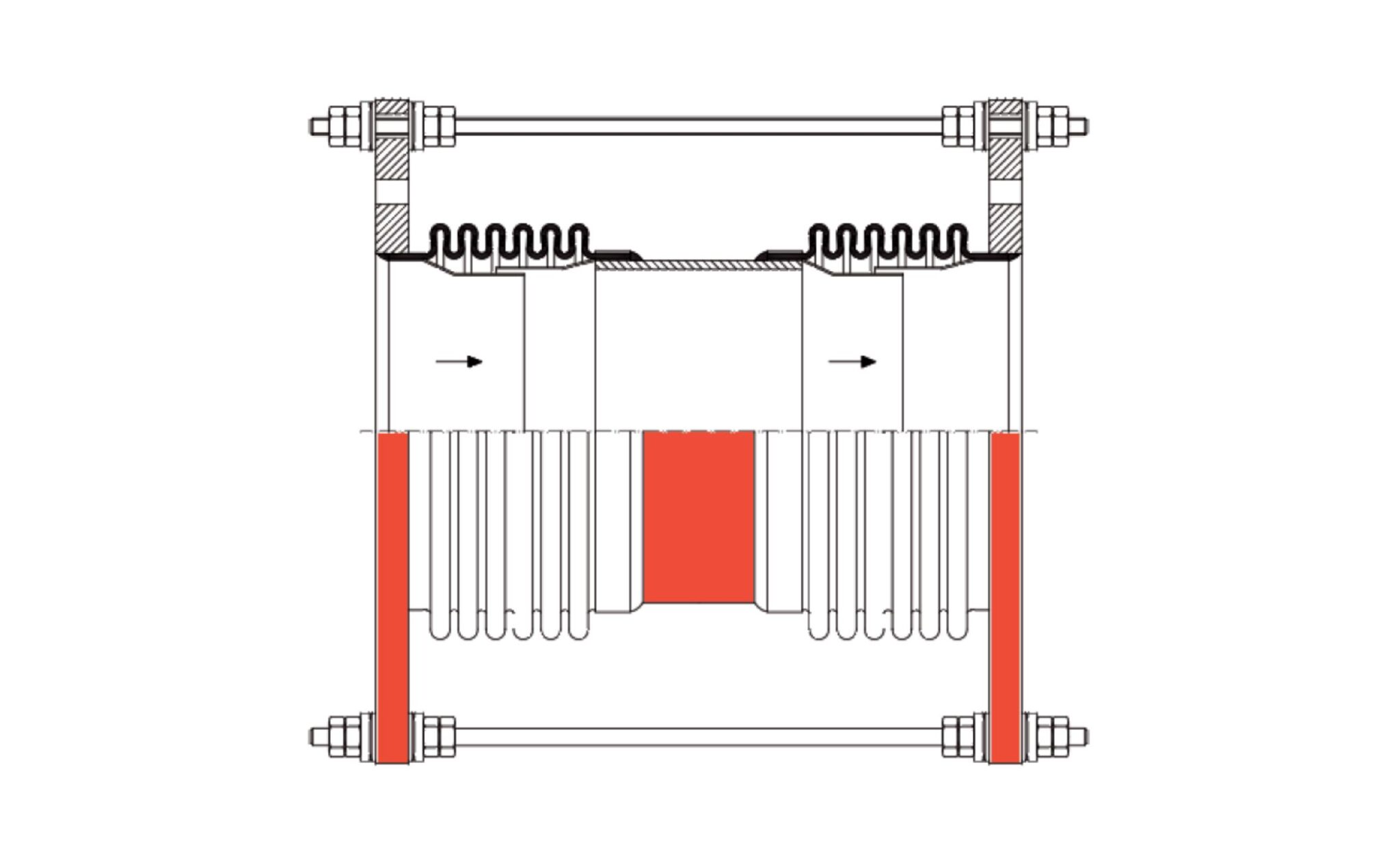

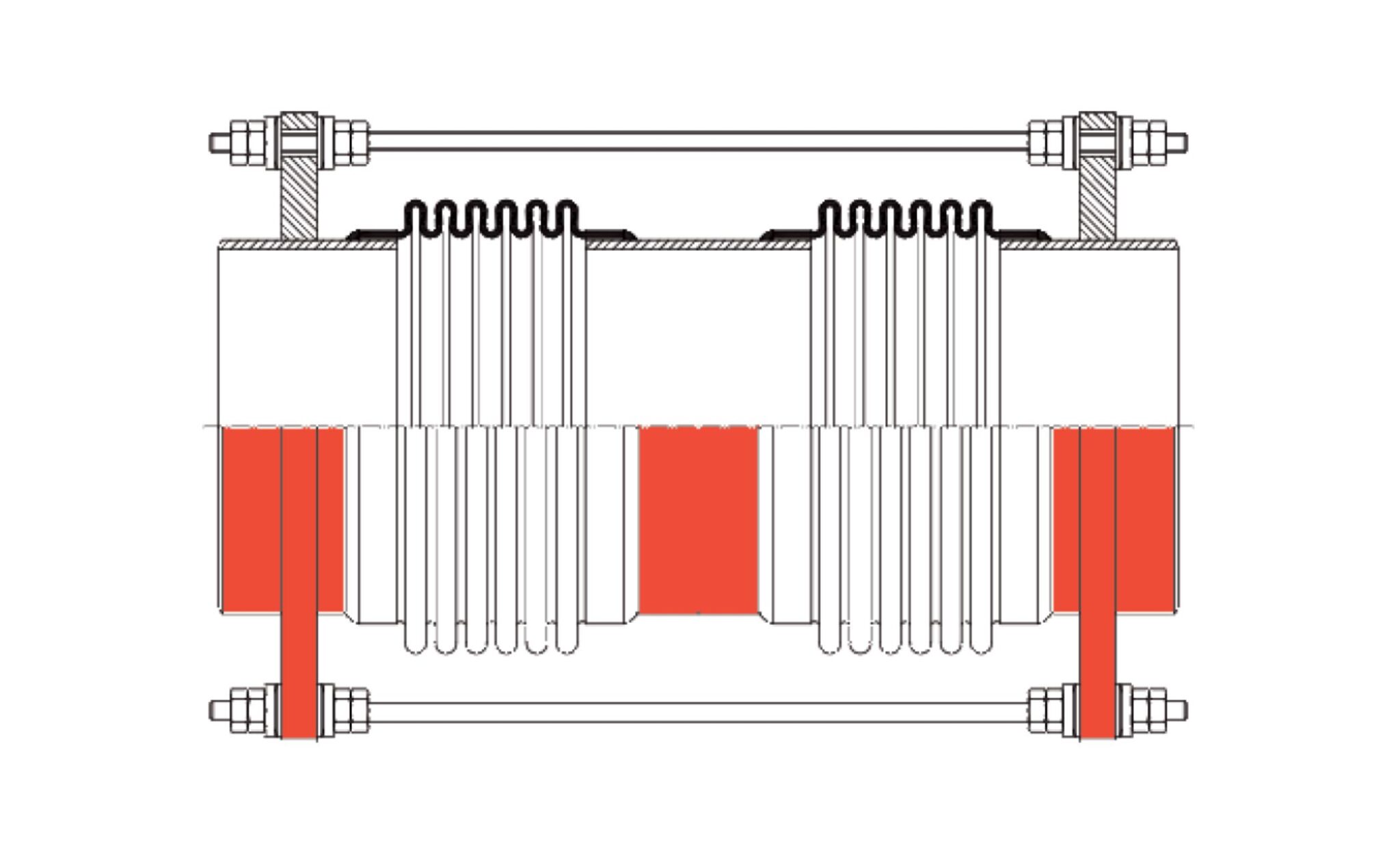

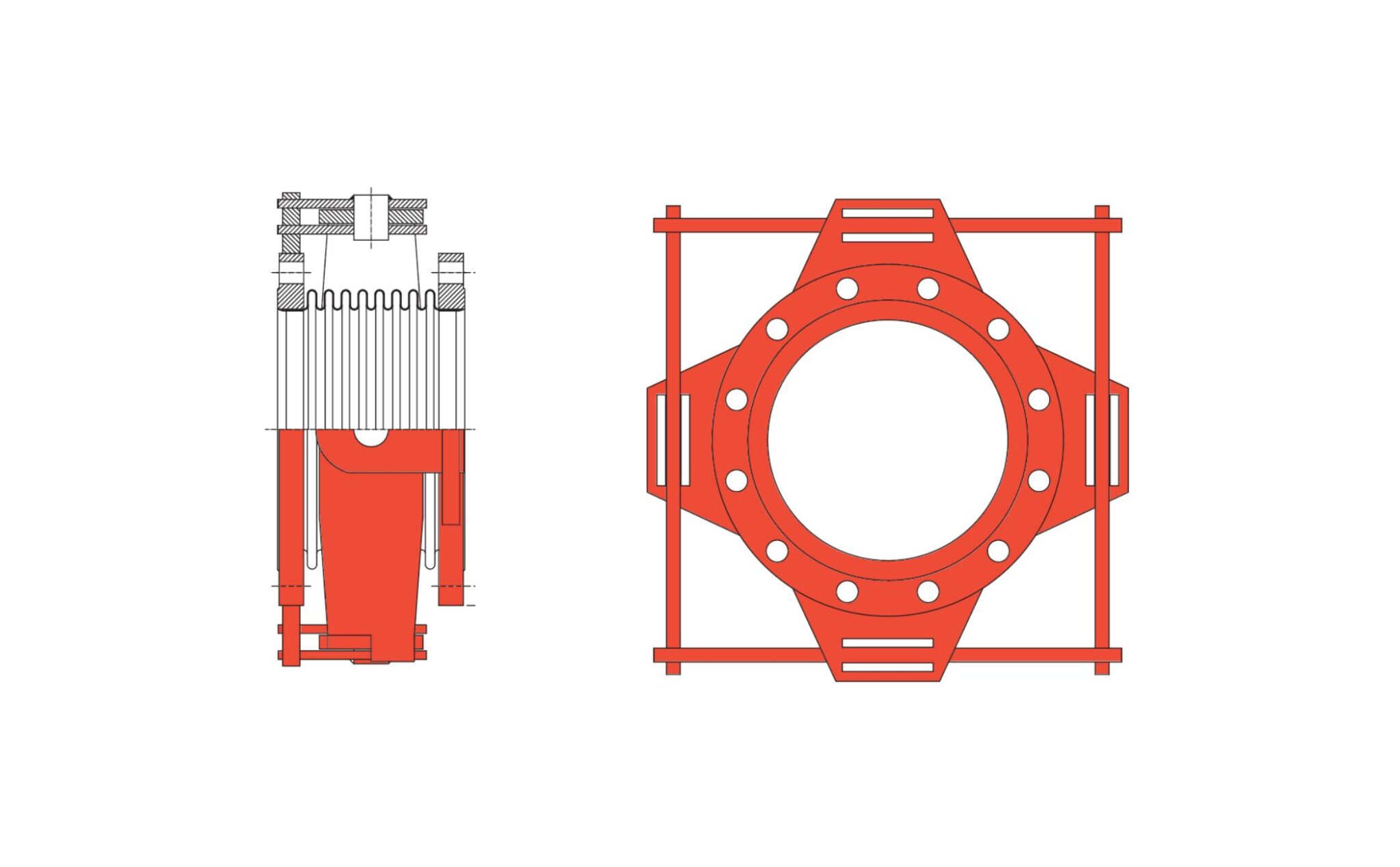

L Series

High Pressure - Lateral Movement

Expansion joints with tie rods to absorb lateral movements and vibrations without transmitting pressure forces to the system. Ideal for piping in “L”, “U” or direction‑change configurations.

✓ Pressure: PN 6 to PN 150 bar; lateral movements up to 40 mm in catalog, any higher designed specifically.

✓ Anti-vibration capability: absorbs oscillations from pumps, compressors, and rotary equipment

✓ Configuration: two or more expansion joints with adjustable tie rods; rigid or flexible version

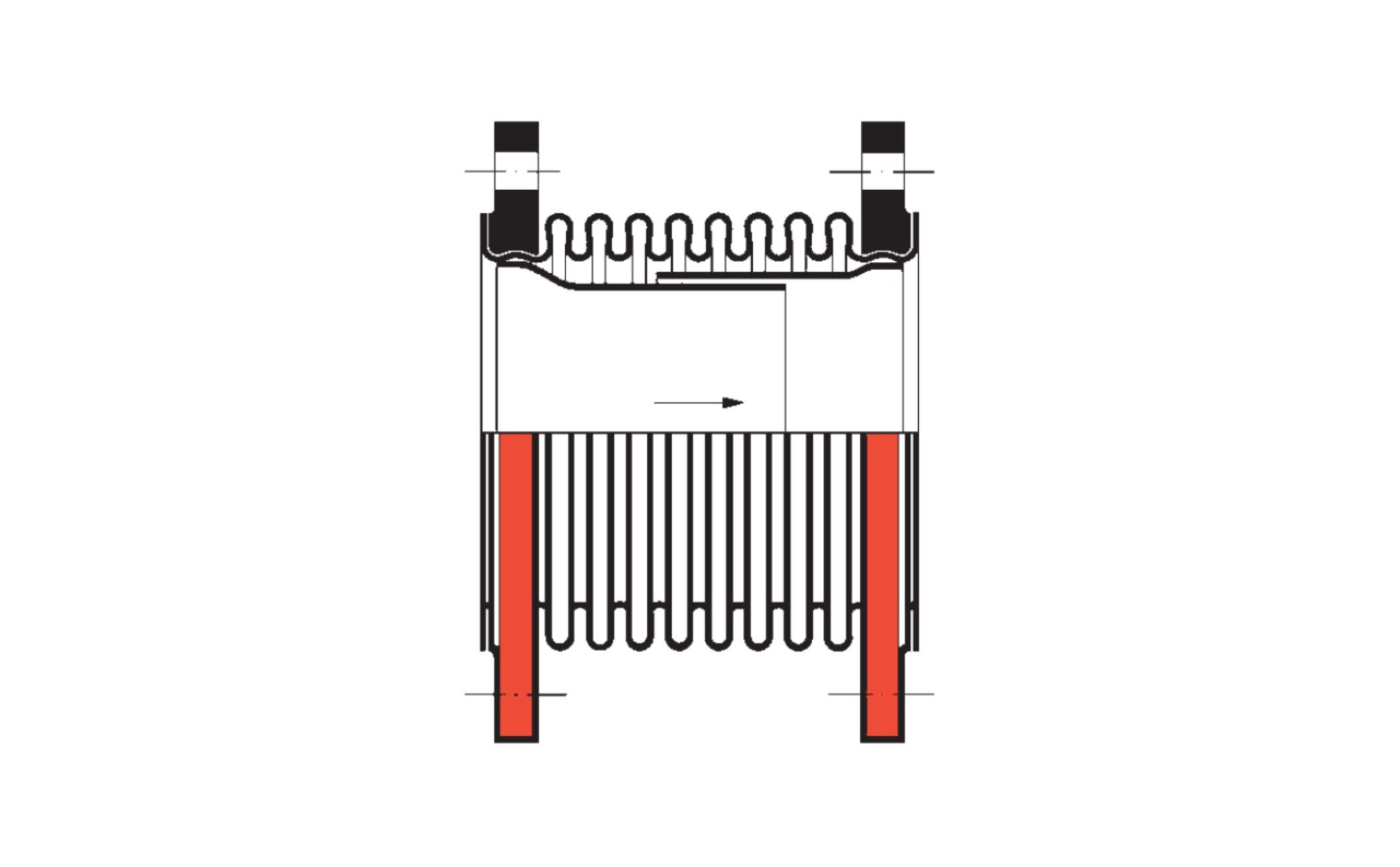

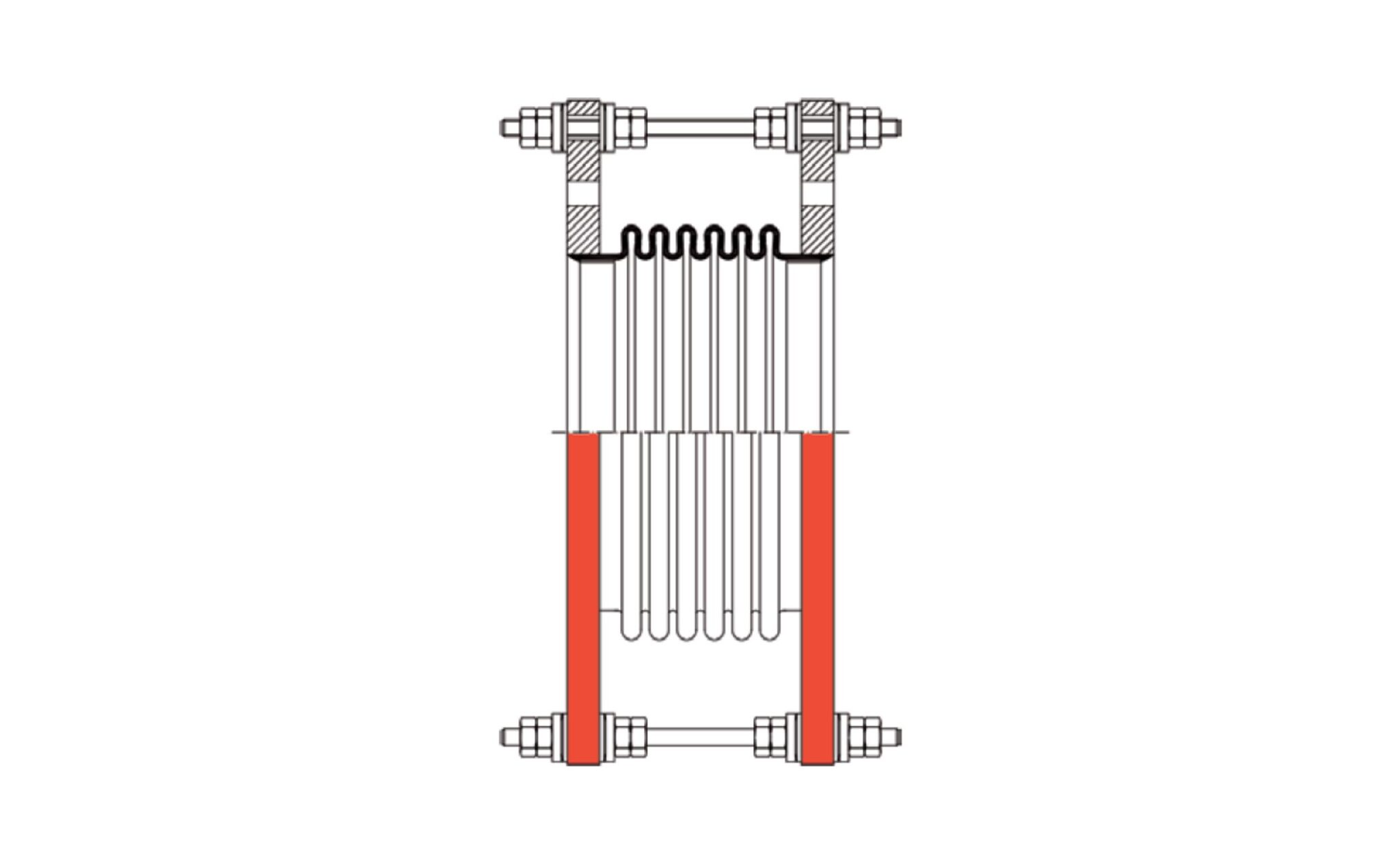

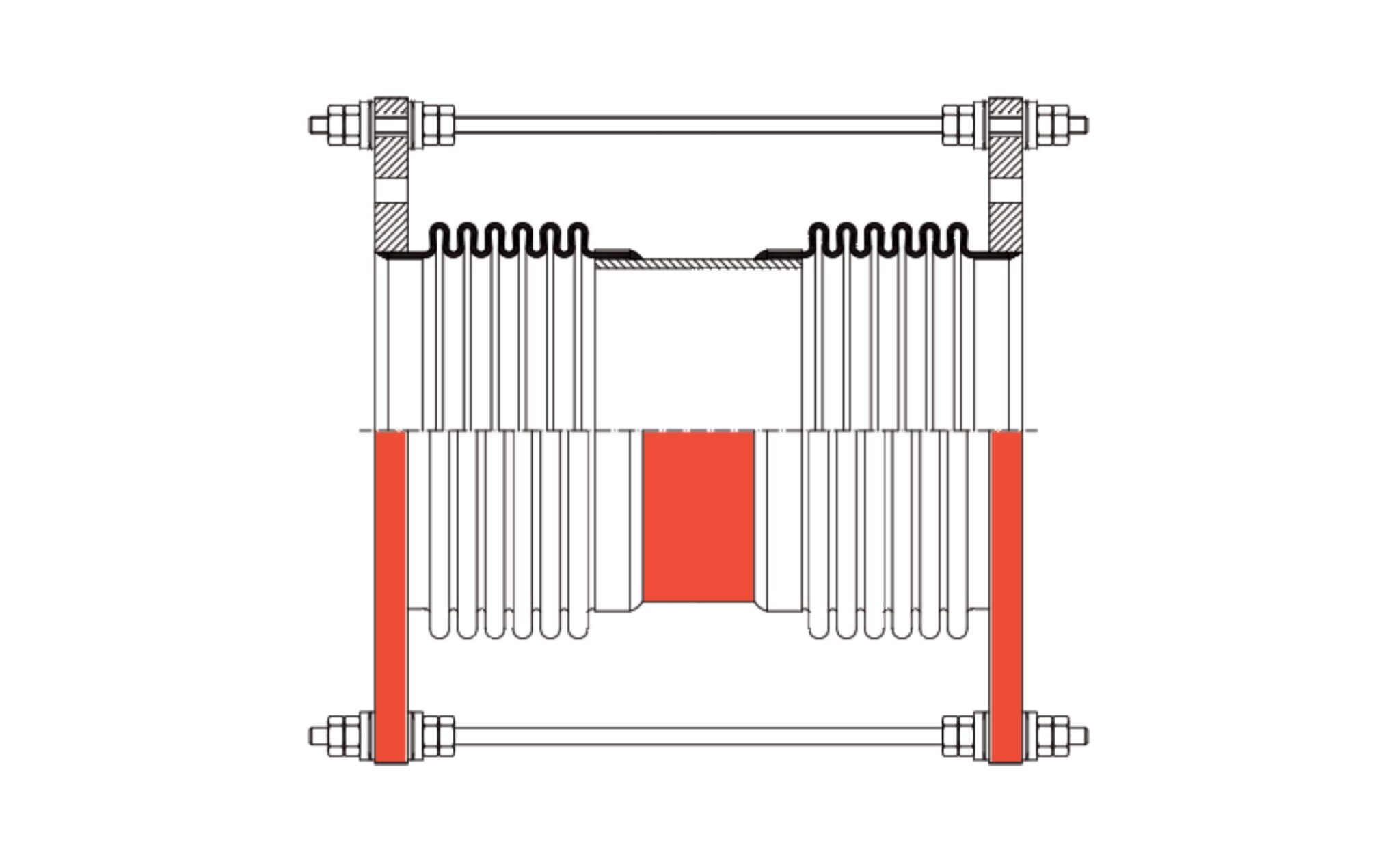

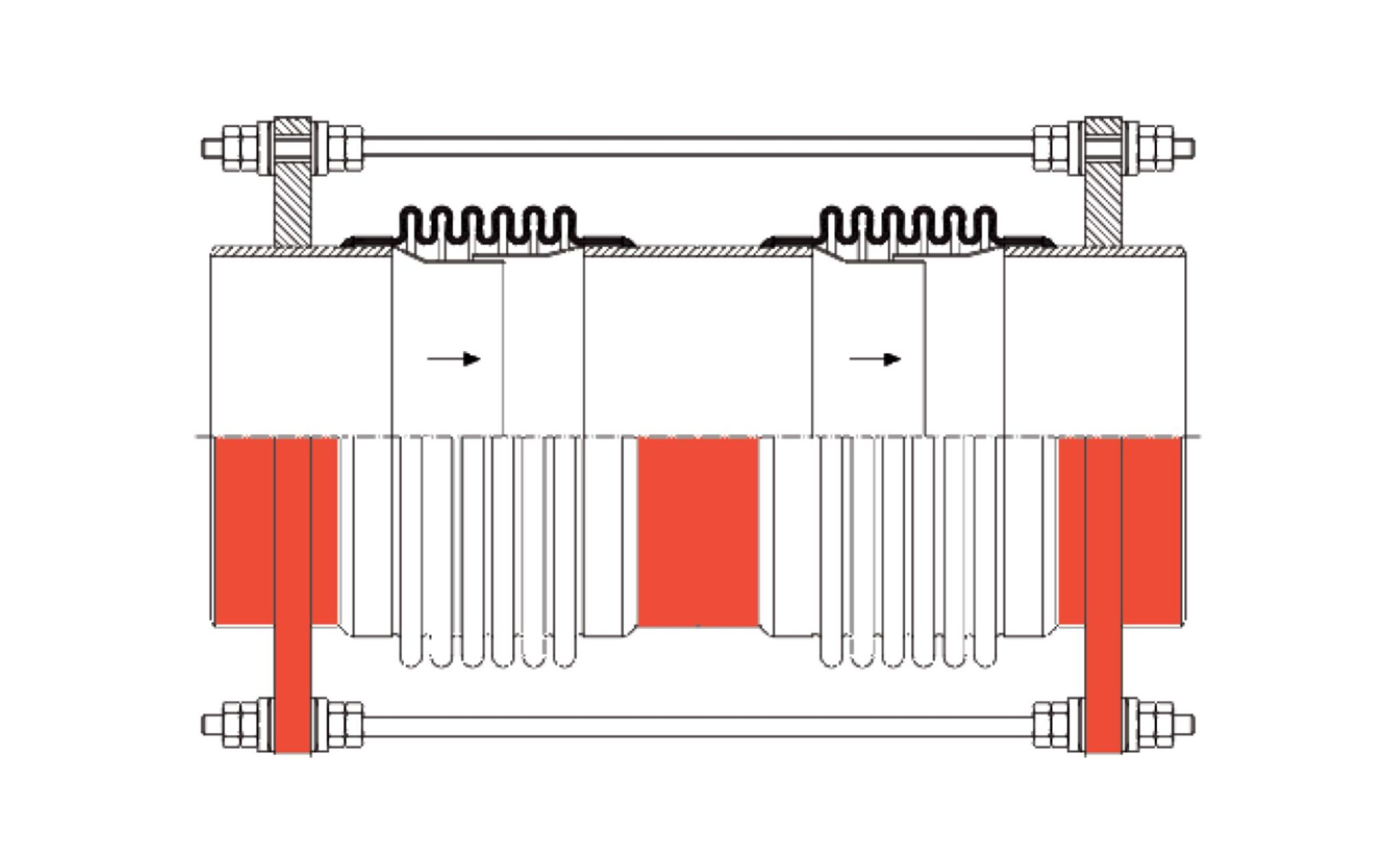

A Series

High Pressure – Angular Movement

Angular‑movement compensators to absorb misalignments and rotations in piping. Available in single‑hinge and spherical gimbal versions for maximum freedom of movement.

✓ Angular movement: up to 20–25º per compensator (configured in pairs or trios)

✓ Multi-directional systems: pairs of angular joints for movement in one plane, triads with gimbals for three planes

✓ Configurations: L‑system (3 compensators in “L”), W‑system, U‑system depending on installation layout

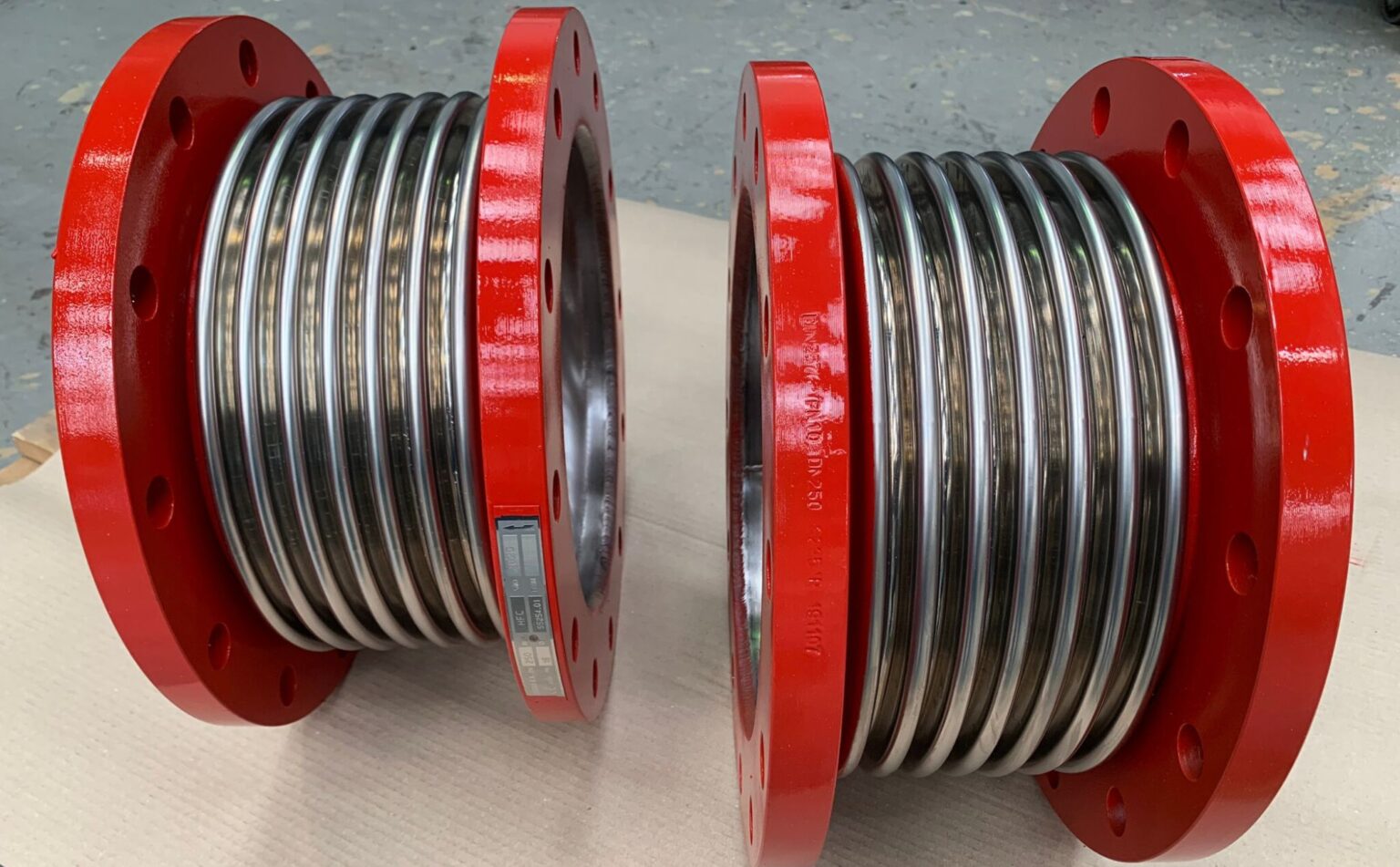

Custom Design and Manufacturing

At Coraci we offer comprehensive advanced engineering solutions for the customization of expansion joints. de expansión. We customize each expansion joint to the unique requirements of the customer's application, adapting to their specific parameters in accordance with EJMA and EN14917 standards, ensuring maximum reliability and service life to guarantee performance, durability, and utmost safety.

Every Coraci compensator is manufactured with a focus on quality, traceability and maximum safety for critical applications such as energy, petrochemicals, desalination and large infrastructures.

✓ Custom design according to the client’s drawings, conditions and specifications

✓ FEA simulation and calculation, ensuring optimal behaviour under pressure and fatigue

✓ Selection of materials (AISI 304, 316, Inconel, Hastelloy) according to chemical and thermal requirements

✓ Rapid prototyping and certification according to CE and PED standards

✓ Direct on‑site assistance and technical training for safe installation