Flexible Hoses

Flexible conduits for strain relief and the protection of electrical cables

Catalogued according to Coraci S.A. standard

Find the joint that best suits your needs

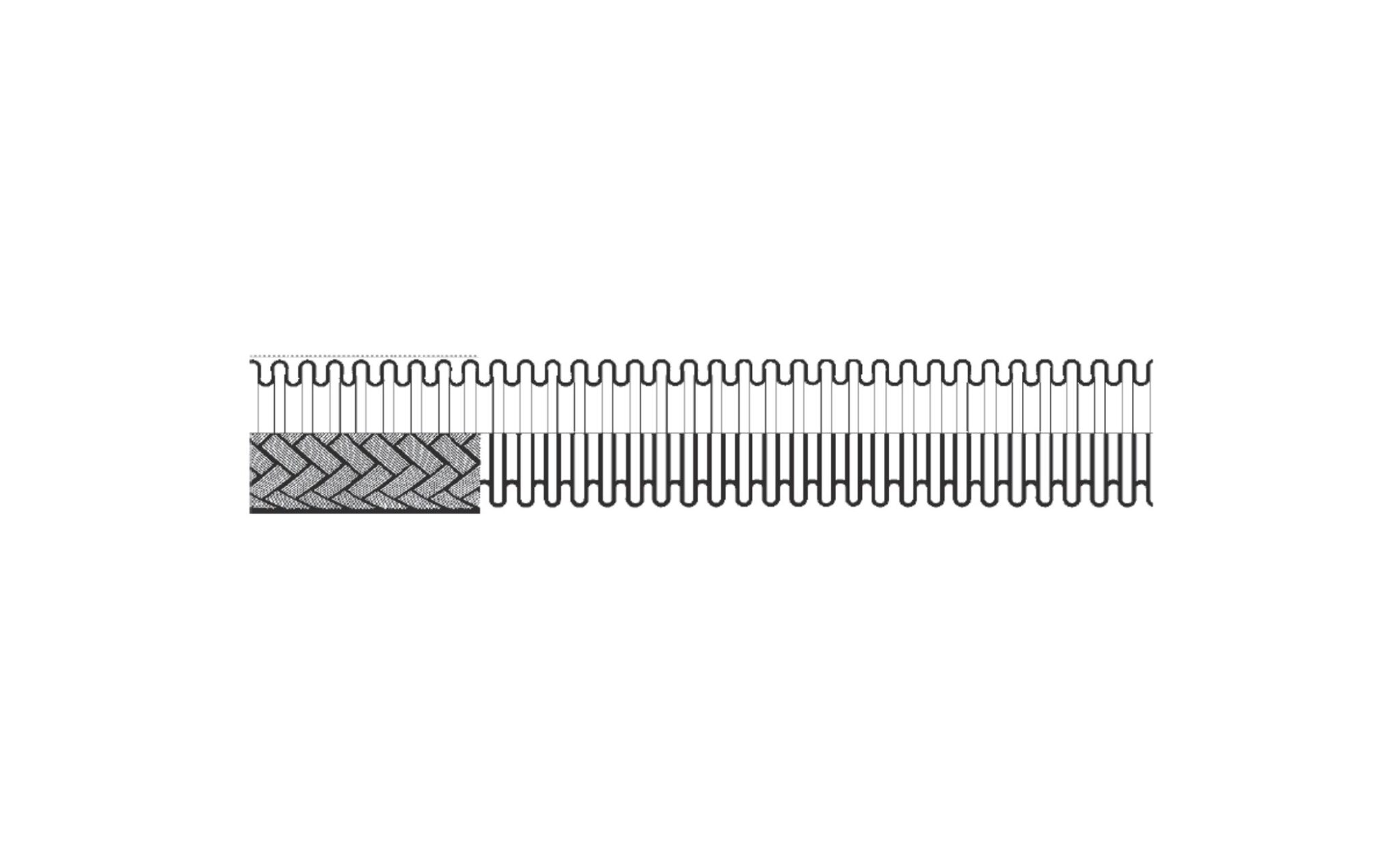

FLECOR© SP

Semi‑heavy Metal Flexible Hose

Metal flexible hose with parallel corrugations of medium wall thickness, manufactured in stainless steel AISI 321 or 316 with a single layer of steel wire braid. Designed for medium-pressure flexible connections between industrial equipment, high-temperature systems, and applications with moderate vibrations.

✓ Pressure range: PN 6 to PN 80 bar depending on material and diameter

✓ Diameters: DN 10 to DN 300; optimized bending radius for compact spaces

✓ Connection type according to EN, ASME, FIL, DIN standards, etc., can be supplied.

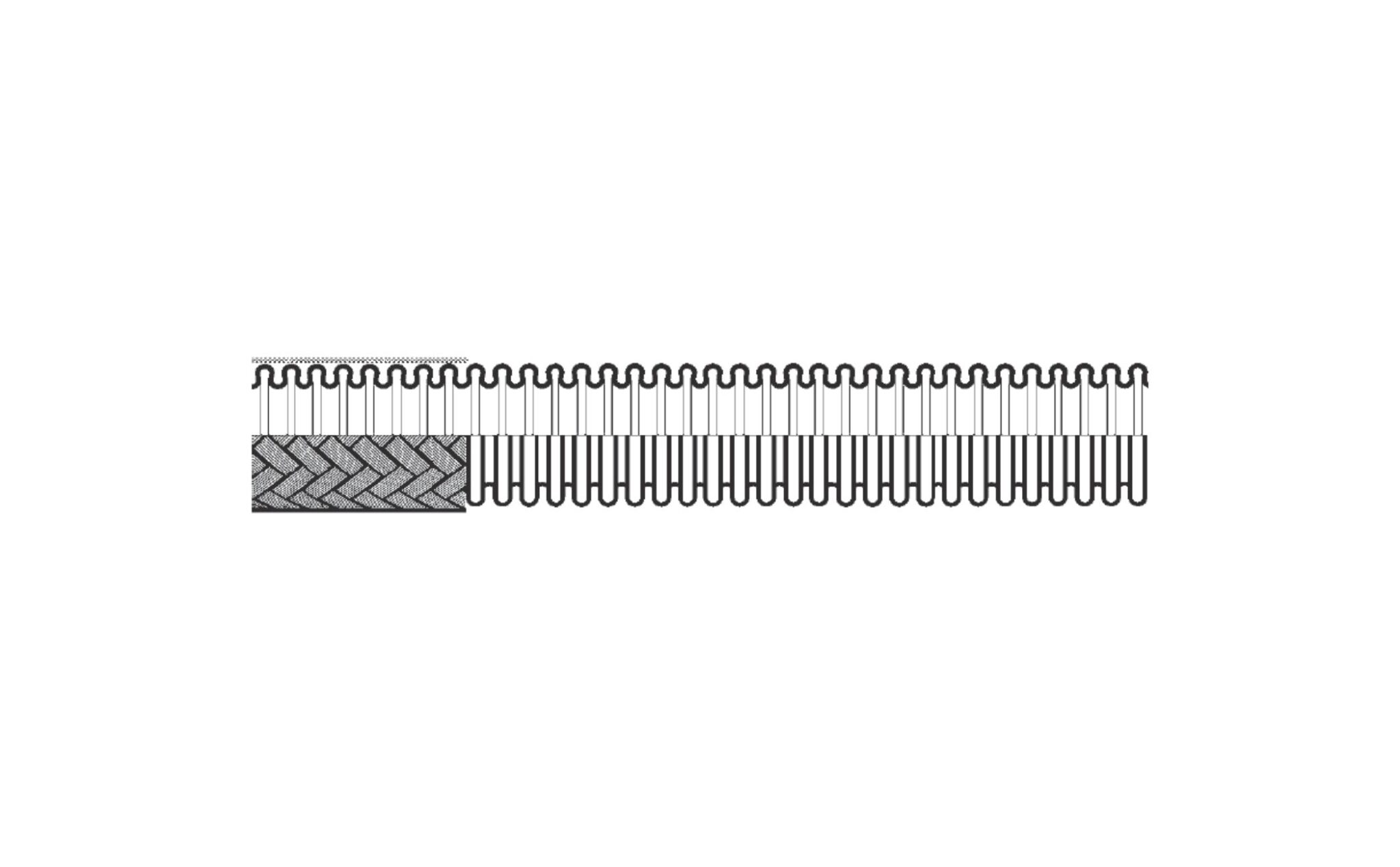

FLECOR© P

Heavy‑duty Metal Flexible Hose

High-strength metal flexible hose with thick-walled parallel corrugations featuring double or triple steel braid layers. Specially designed for high-pressure and extreme-temperature lines in petrochemical plants, power generation, and industrial combustion systems.

✓ Pressure range: PN 6 to PN 300 bar; temperatures up to 400ºC or higher depending on material

✓ Diameters: DN 20 to DN 150; optimized bending radius for compact spaces

✓ Connection type according to EN, ASME, FIL, DIN standards, etc., can be supplied.

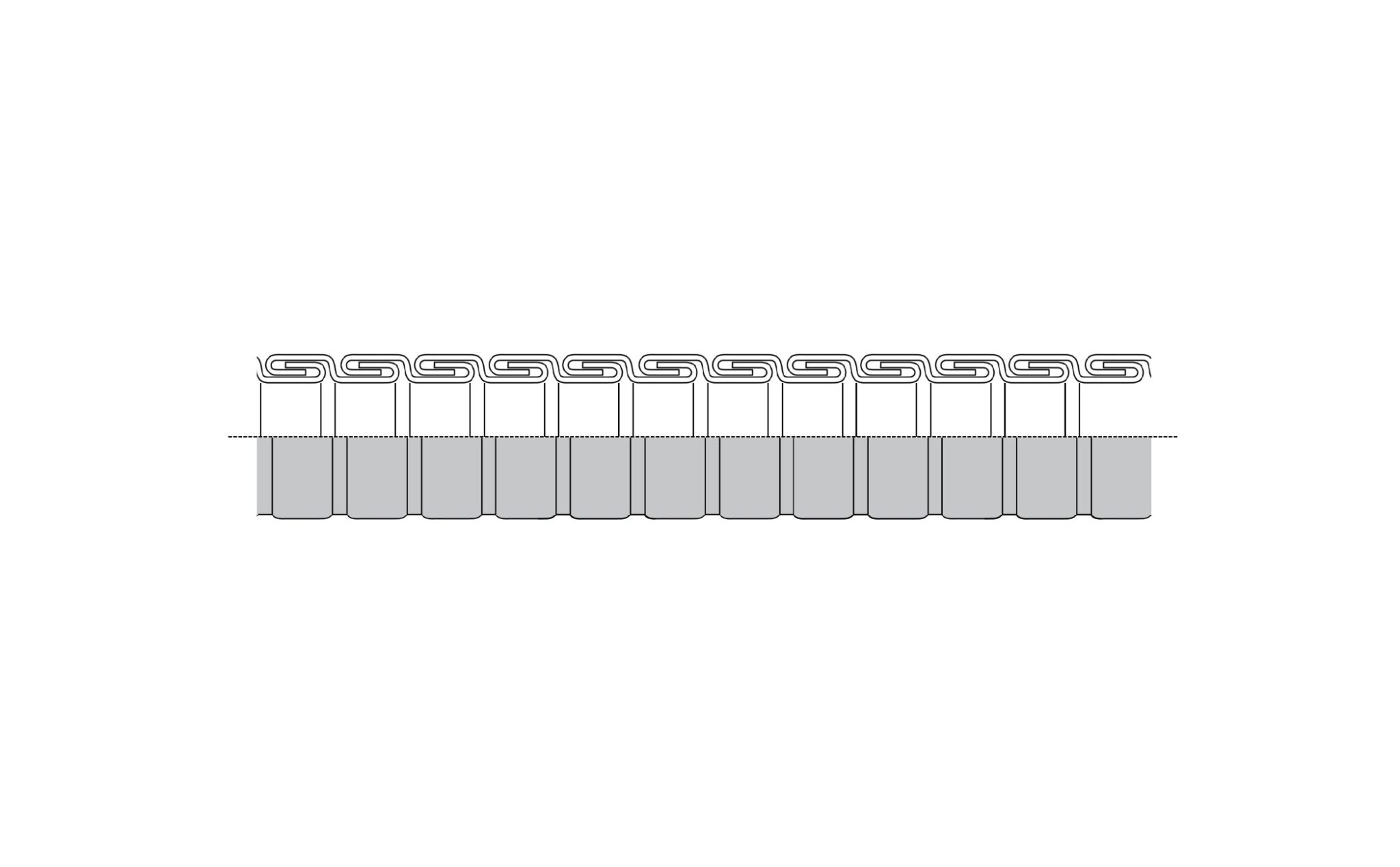

ANACONDA SEALTITE©

Protection and Covering Conduit for Electrical Installations

Metal protection and covering conduit for electrical installations with a high‑strength metallic armour made of galvanised steel, aluminium or bronze, externally coated with a thermoplastic sheath (PVC, polyurethane, silicone) resistant to weather, humidity, dust, corrosion and mechanical damage.

✓ Standard types: E.F. (extra‑flexible), H.C. (resistant to cold/heat), O.R. (oil/grease‑resistant), C.N.P. (special applications)

✓ Temperature range: -45ºC to +105ºC (H.C. models); VDE, DEMKO, NEMKO, UL, NEC and ATEX certifications.

✓ Diameters: DN 6 to DN 50 mm; standard connections with ANAMET IP67/IP68 fittings; easy assembly and disassembly.

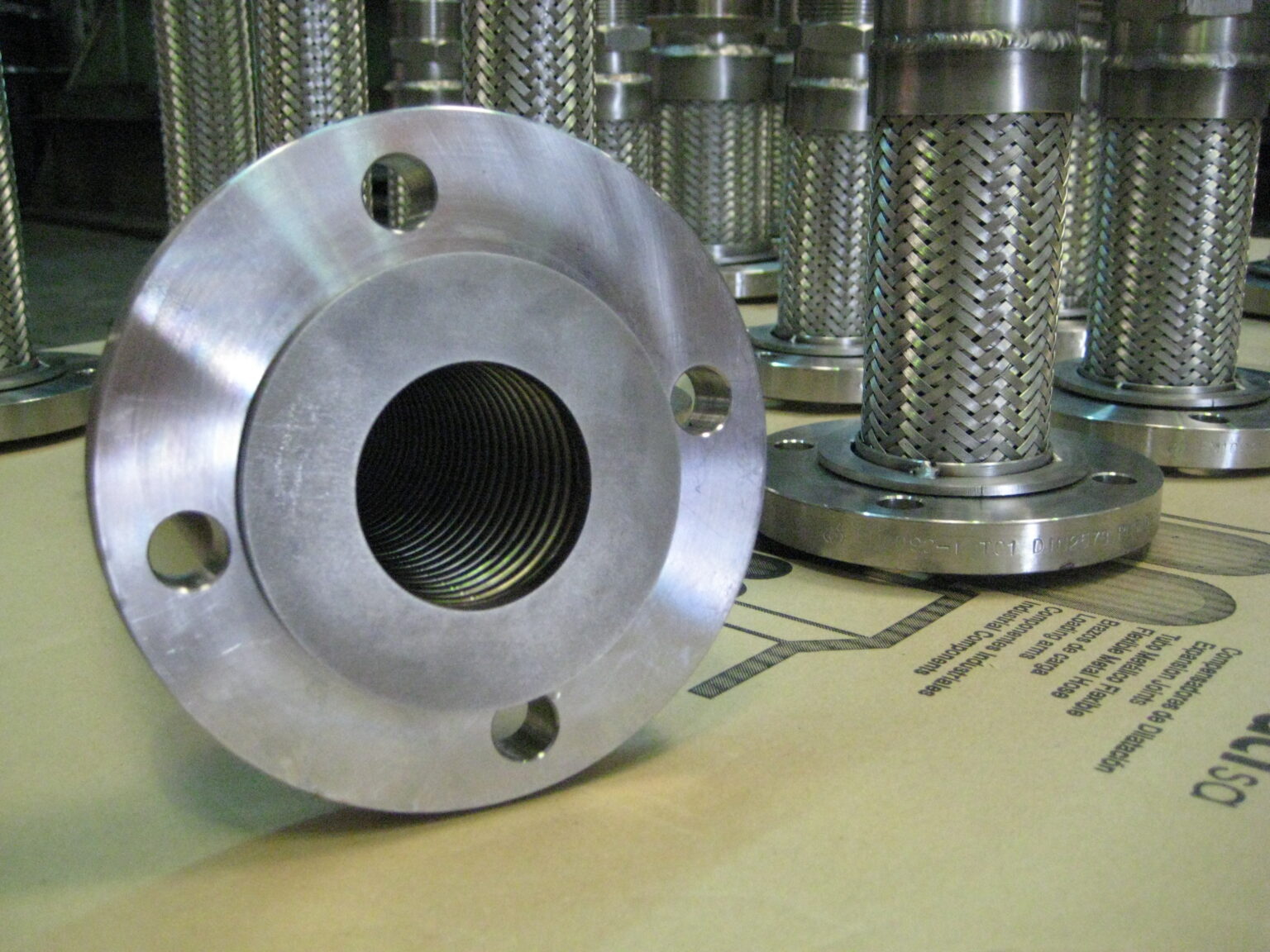

Custom Design and Manufacturing

At Coraci we offer comprehensive advanced engineering solutions for the customization of expansion joints. de expansión. We adapt each compensator to the unique requirements of the customer’s application, adjusting to the client’s specific parameters in accordance with EJMA and EN14917, ensuring maximum reliability and service life to guarantee performance, durability and maximum safety.

Every Coraci compensator is manufactured with a focus on quality, traceability and maximum safety for critical applications such as energy, petrochemicals, desalination and large infrastructures.

✓ Custom design according to the client’s drawings, conditions and specifications

✓ FEA simulation and calculation, ensuring optimal behaviour under pressure and fatigue

✓ Selection of materials (AISI 304, 316, Inconel, Hastelloy) according to chemical and thermal requirements

✓ Rapid prototyping and certification according to CE and PED standards

✓ Direct on‑site assistance and technical training for safe installation