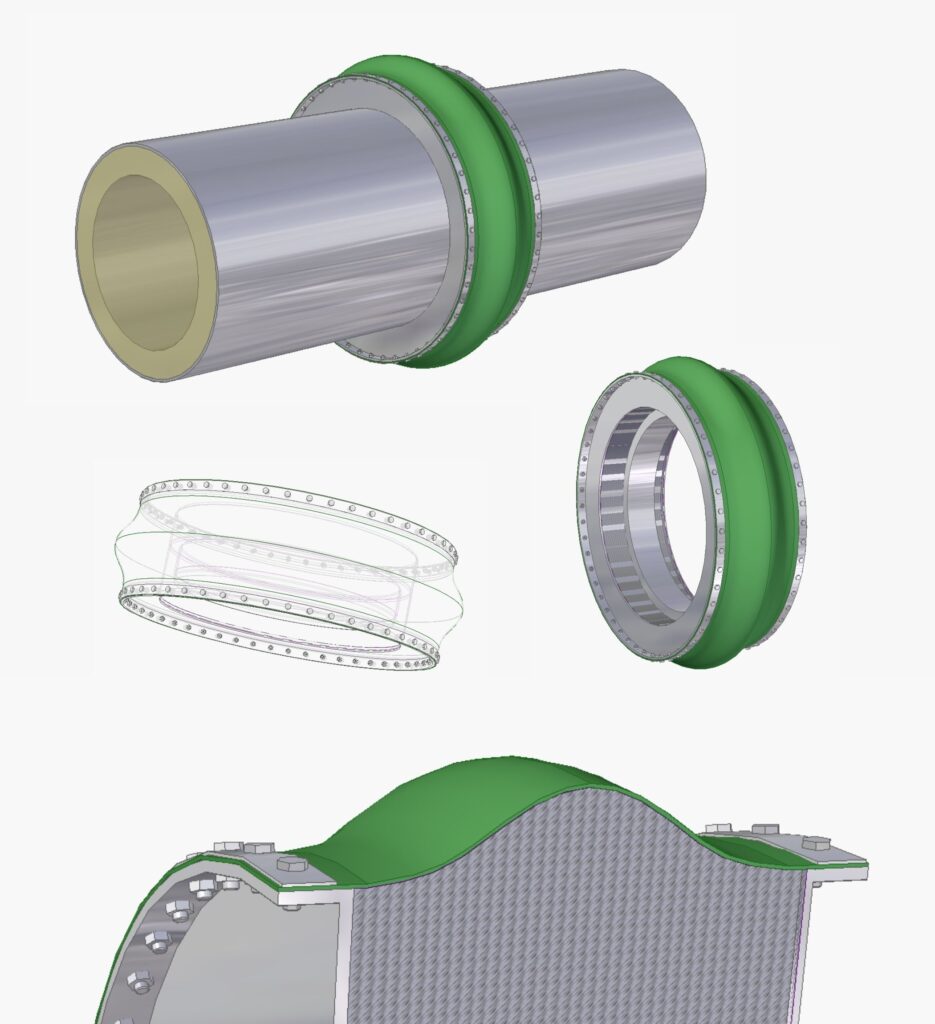

Textile Joints

Flexible solutions for power plants, the steel industry, and demanding processes.

Catalogued according to Coraci S.A. standard

Find the joint that best suits your needs

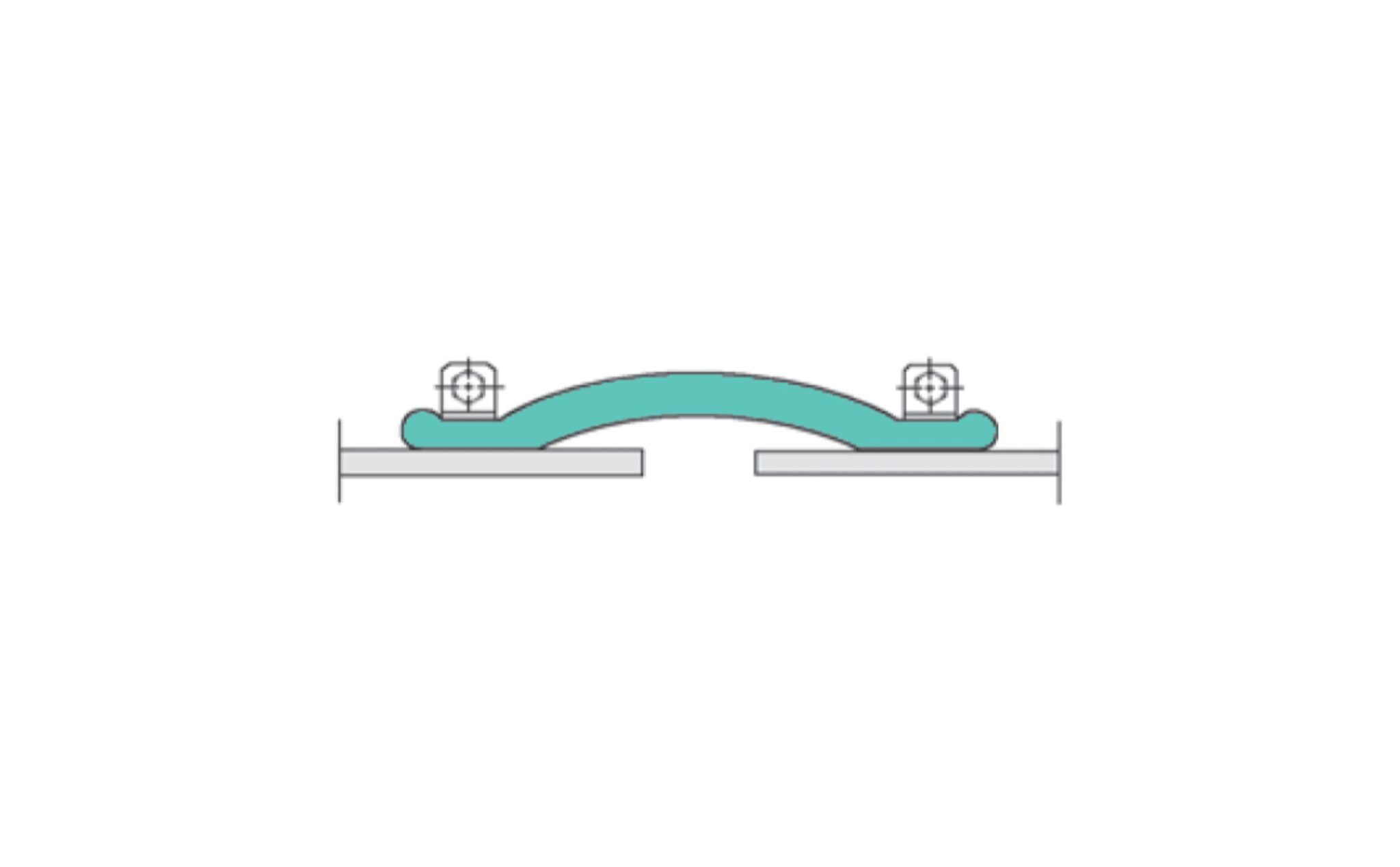

Type I

(±) Pressure

Textile joint for direct fixing to the duct using clamps. Suitable for air and gas ducts at medium temperature.

✓ Fast installation without flanges, using metal clamps.

✓ Temperature range: -5ºC to +400ºC depending on the selected textile material.

✓ Ideal for large diameters and custom geometries in ventilation and clean‑air systems.

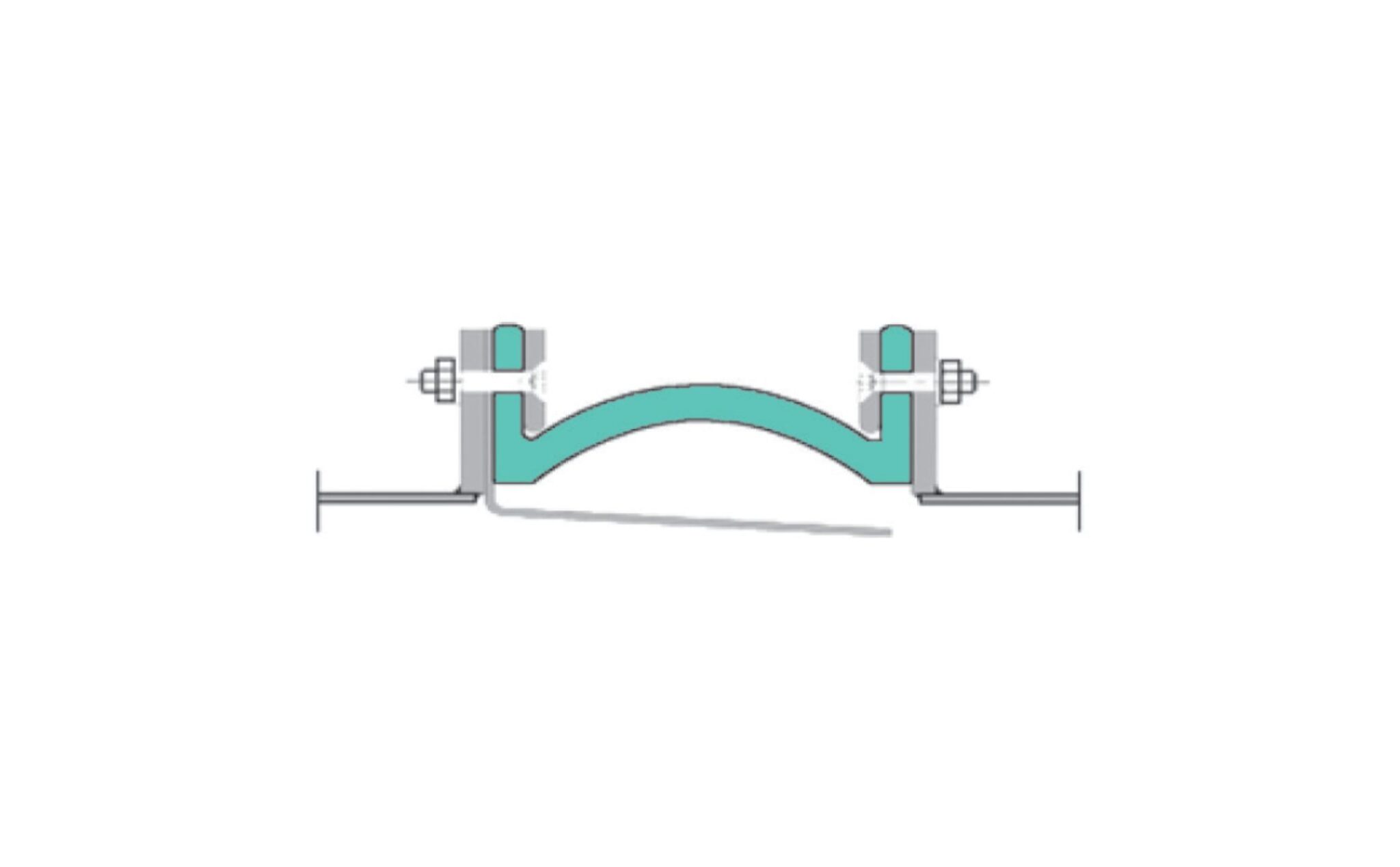

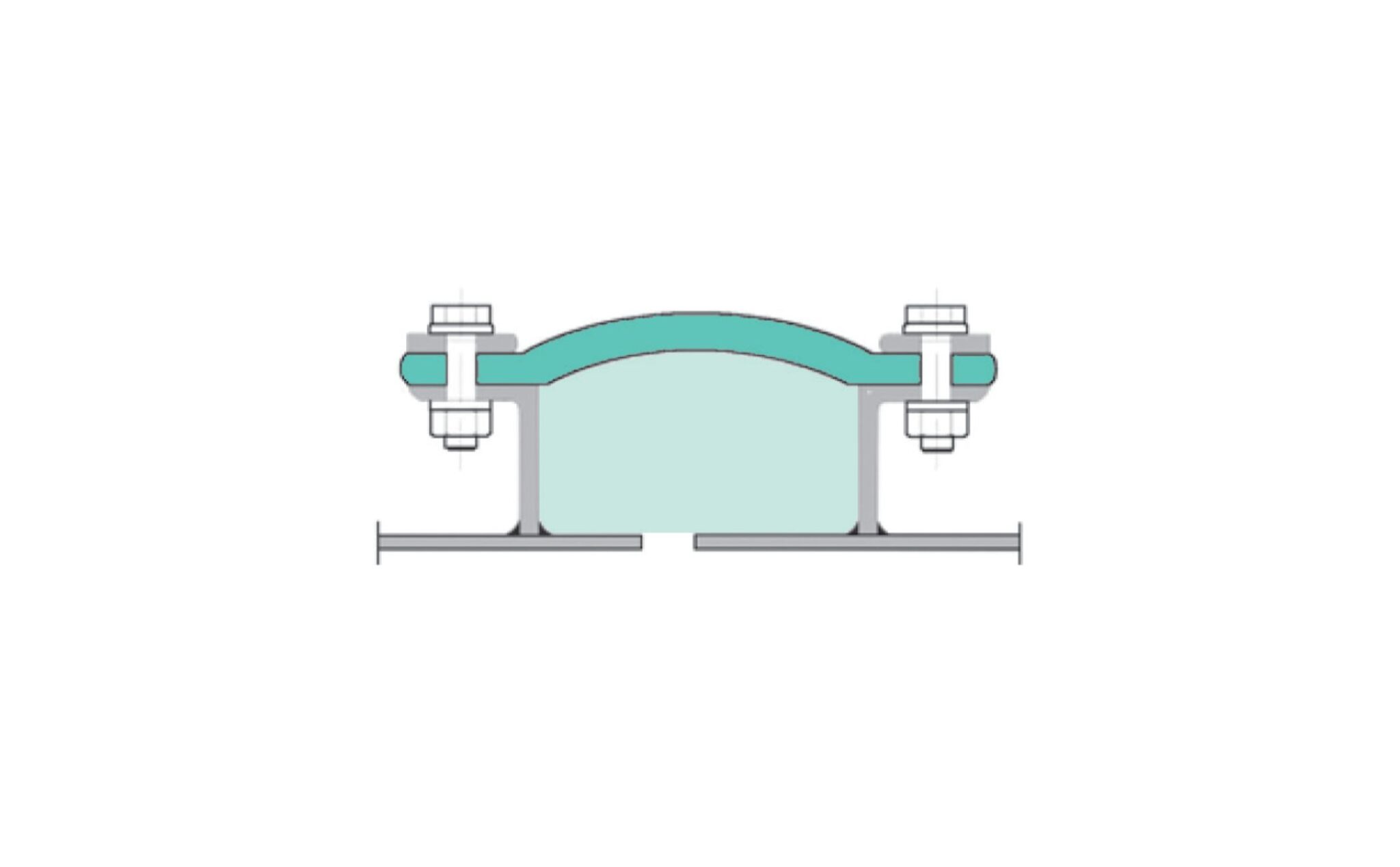

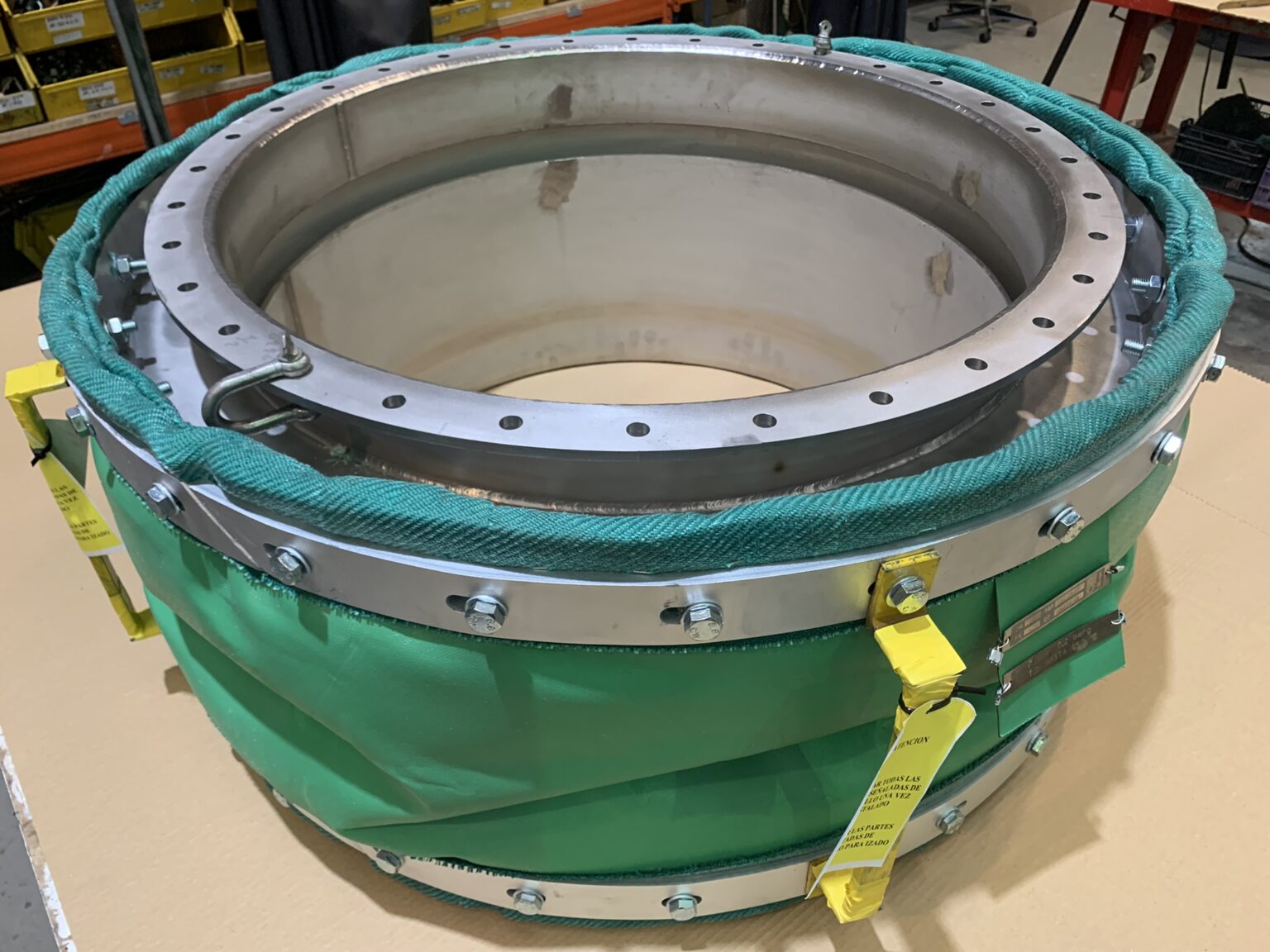

Type II

(+) Pressure

Textile joint installed between backing flanges and counter‑flanges, especially recommended for positive pressure, air, gases and fumes.

✓ Robust fixing for systems with positive internal pressure difference.

✓ Extended temperature range: -5ºC to +525ºC, depending on the selected material.

✓ Used on boiler outlets, industrial ducts and process equipment.

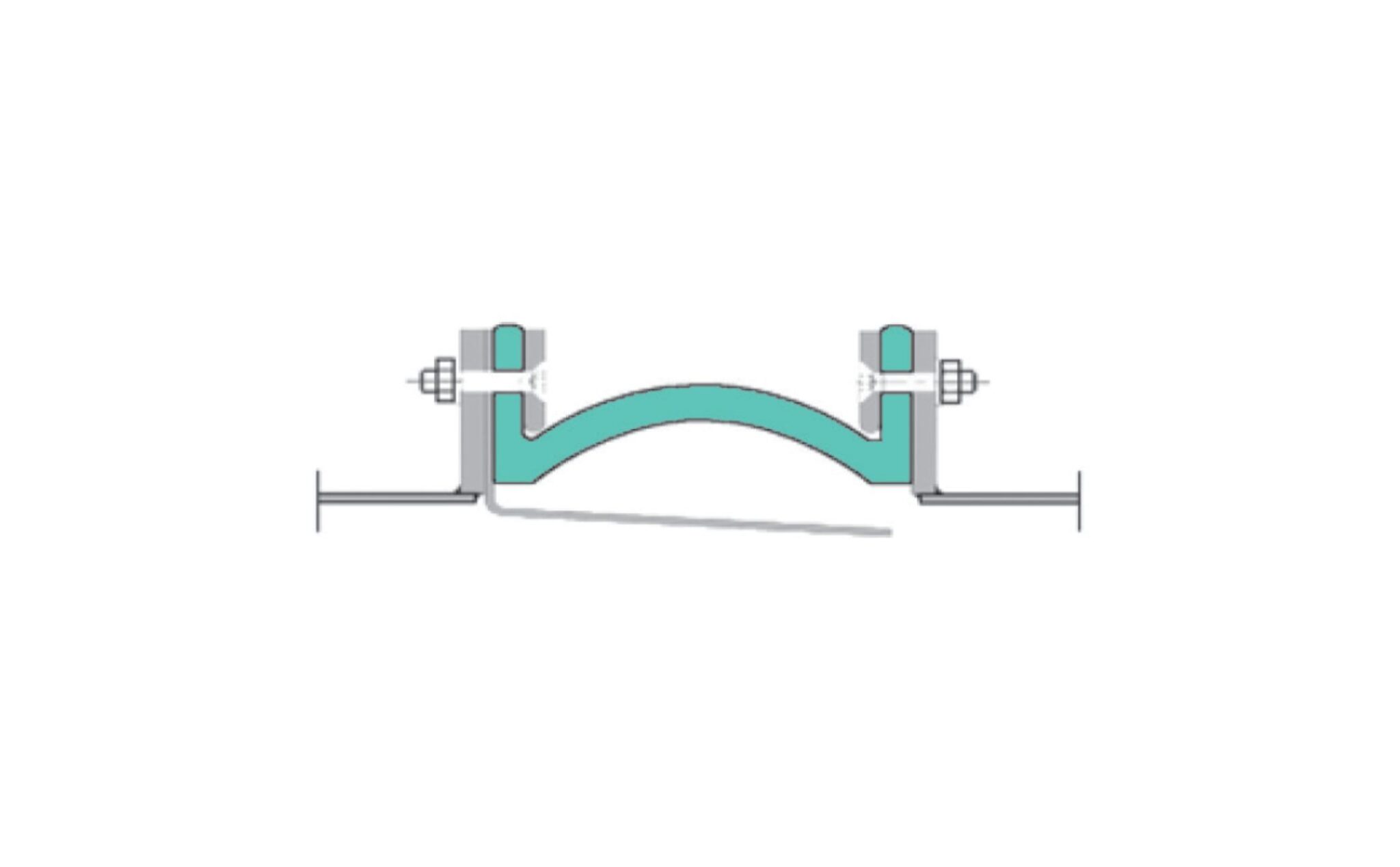

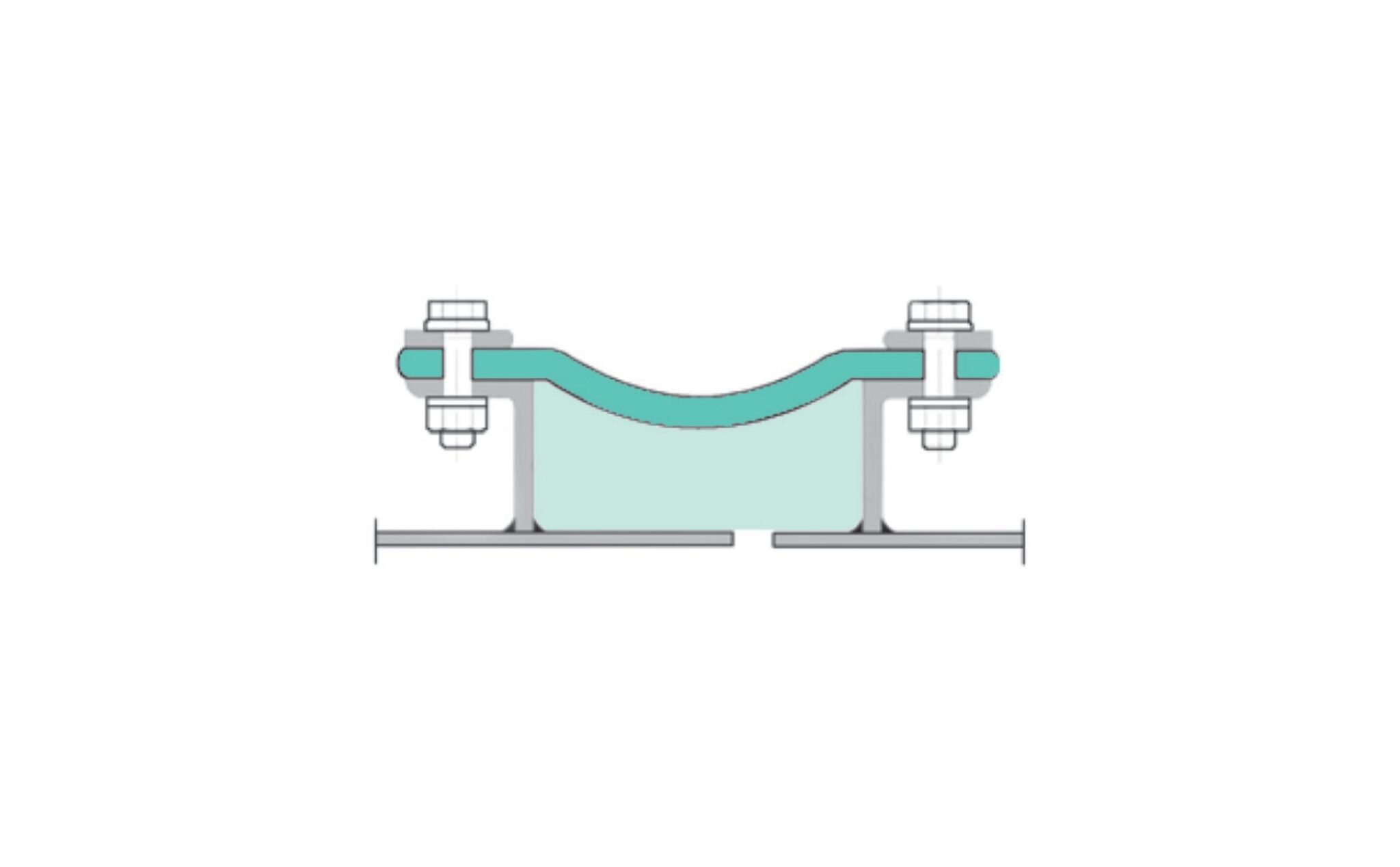

Type III

(-) Pressure

Textile joint for fixing between counter‑flanges and backing flanges in negative‑pressure ducts. Especially designed for extraction and vacuum processes.

✓ Optimum tightness in systems with vacuum or fume and vapor extraction.

✓ Temperature range: -5ºC to +525ºC; multilayer fabrics for maximum durability.

✓ Applications: industrial chimneys, dust extractors and aggressive gases.

Type IV

(+) Pressure

Textile joint for installation between counter‑flanges parallel to the duct and external backing flanges, used on positive‑pressure lines and at extreme temperatures.

✓ Recommended for high temperatures up to +1,100ºC.

✓ Large sealing surface for large‑section ducts with complex geometry.

✓ Suitable for thermal plants, combustion systems and the steel industry.

Type V

(-) Pressure

Textile joint for installation between parallel counter‑flanges and external flanges, in negative‑pressure systems exposed to extreme temperatures.

✓ Maximum design flexibility for negative pressure and demanding thermal cycles.

✓ Reinforced materials for highly corrosive environments and temperatures up to +1,100ºC.

✓ Commonly used in desulfurization, industrial filters, exhaust ducts and extraction systems.

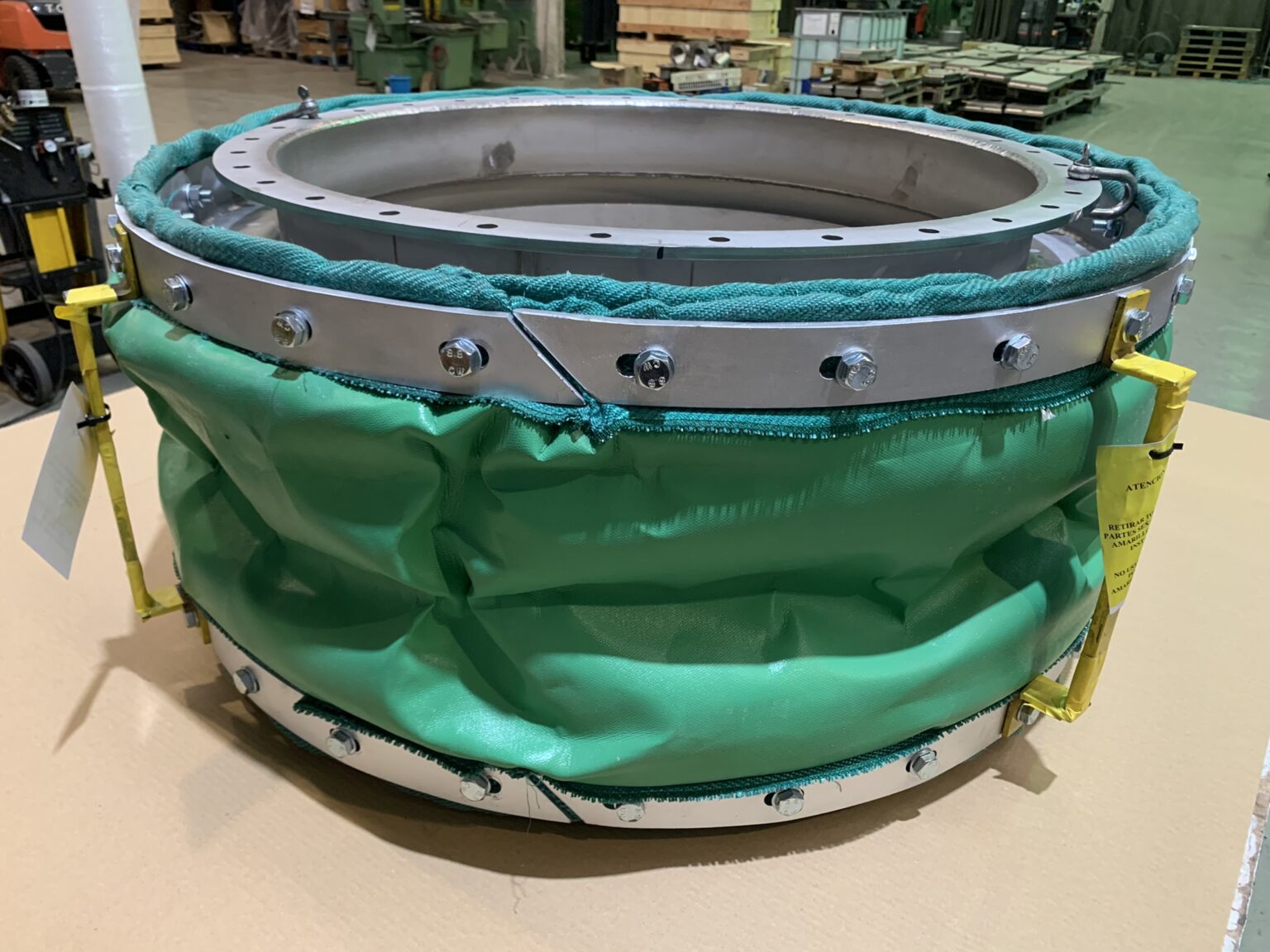

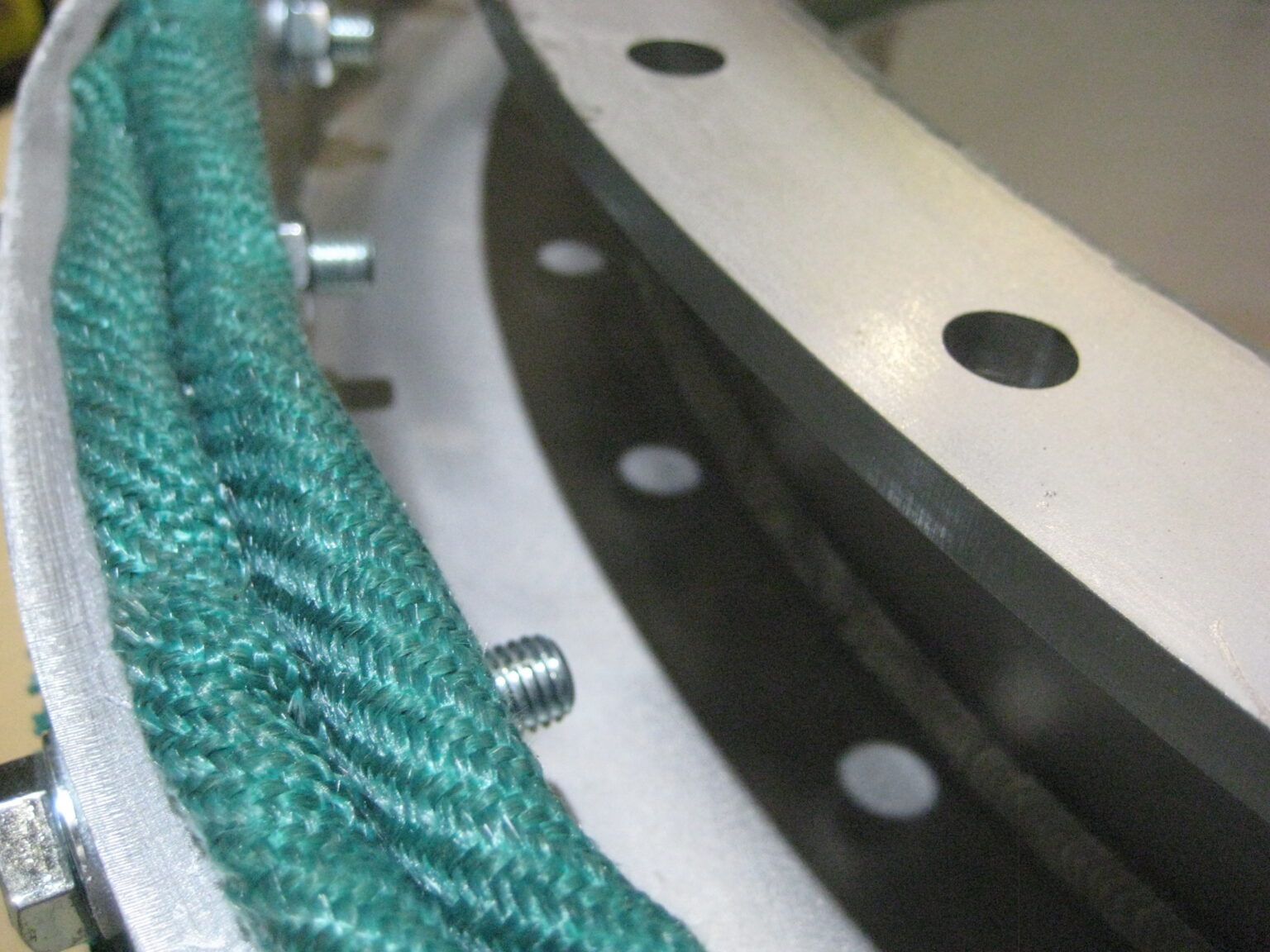

Custom Design and Manufacturing

At Coraci we offer comprehensive advanced engineering solutions for the customization of expansion joints. de expansión. Adaptamos cada compensador a los requisitos únicos de la aplicación del cliente, adaptando a los parámetros específicos del cliente, conforme a EJMA, ASME y EN 14917, asegurando máxima fiabilidad y vida útil. para garantizar rendimiento, durabilidad y máxima seguridad.

Every Coraci compensator is manufactured with a focus on quality, traceability and maximum safety for critical applications such as energy, petrochemicals, desalination and large infrastructures.

✓ Custom design according to the client’s drawings, conditions and specifications

✓ FEA simulation and calculation, ensuring optimal behaviour under pressure and fatigue

✓ Selection of materials (AISI 304, 316, Inconel, Hastelloy) according to chemical and thermal requirements

✓ Rapid prototyping and certification according to CE and PED standards

✓ Direct on‑site assistance and technical training for safe installation